1200W Industrial Oil Bottle Labeling Equipment Electric Driven Type

Product Details:

| Place of Origin: | ZhangJiaGang City,JiangSu Province of China |

| Brand Name: | Fill Pack |

| Certification: | CE,ISO9001 |

| Model Number: | TB630-2 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set for oil bottle labeling machine |

|---|---|

| Price: | USD$11500-13500/set |

| Packaging Details: | sea worthy packing |

| Delivery Time: | 5-15 days |

| Payment Terms: | L/C, D/A, D/P, T/T, , MoneyGram |

| Supply Ability: | 15 sets/month |

|

Detail Information |

|||

| Driven Type: | Electric | Bottle Diameter: | 30~90 Mm (special Size Can Be Customized) |

|---|---|---|---|

| Bottle Height: | 30~200 Mm | Voltage: | 220V/50Hz |

| Dimension: | L 2500mm * W 1300mm * H 1400mm | Material: | Stainless Steel 304, Aluminum Alloy 6061 |

| High Light: | industrial labeling systems,sticker labeling machine |

||

Product Description

1200W industrial oil bottle labeling machine for automatic system PLC control

Product Description

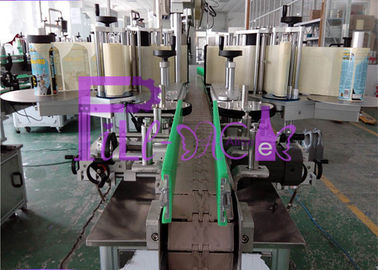

- This oil bottle labeling machine is suitable for all kinds of bottles of double-sided self-adhesive labeling, both double-sided labeling the same species, increase production, but also double-sided paste 2 winning model.The entire device has a number of adjusting devices that can be adjusted to meet the labeling requirements of different bottle diameters and label lengths.It is an optimal combination of speed, accuracy, stability, GMP standards, ease of use, and flexibility.

- The labeler will automatically detects the label size and bottle diameter and set the appropriate labeling parameters – a very useful feature for users with multiple products to label. It is an optimal combination of speed, accuracy, stability, GMP standards, ease of use, and flexibility.Backed by a strong engineering team who is ready to provide custom solutions for the unique production needs of different customers.

![]()

Machine details

Technical parameter for oil bottle labeling machine:

| No | Item | Parameter |

| 1 | Main Material | Stainless Steel 304, Aluminum Alloy 6061 |

| 2 | Dimension | L 2500mm * W 1300mm * H 1400mm |

| 3 | Voltage | 220V/50Hz |

| 4 | Power | 1200 W |

| 5 | Production Capacity | 0-40m/min |

| 6 | Labeling Accuracy | +/- 1mm beak edge |

| 7 | Label Roll Core | 76 mm |

| 8 | Label Roll Diameter | 350 mm |

| 9 | Label Width | 10~110 mm (special size can be customized) |

| 10 | Label Length | 20~360 mm (special size can be customized) |

| 11 | Bottle Diameter | 30~90 mm (special size can be customized) |

| 12 | Bottle Height | 30~200 mm (special size can be customized) |

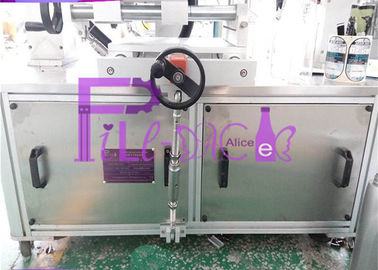

Bottle supporting---bottle top pressing system:

![]()

![]()

Delivery time:

The machines will be made within 25 working days after the bottle design are confirmed.

Payment:

30% T/T deposit within five days after the contract is signed against invoice of the seller. The balance of 70% T/T before shipment.

Our service:

1.Installation & adjustment

After the equipment are arrived at the customer’s site, the customer is responsible for unpacking and arranging the equipment according to the placement drawing; and does under our install-adjust technicians’ guidance. Costs of the staff are decided at last.

2.Training

We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users' technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.The buyer can send staff to our company for learning.

3. Quality assurance

We guarantee the goods offered are brand-new, not used, with latest design and suitable material made, and we guarantee the specification of the equipment is consonance with the contract.We guarantee the line achieve product technical performance indicators within 5 days after feeding operation through the correct guidance of the installation and commissioning.We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. that all belong to our responsibility.

The warranty period is 12 months after acceptance check of the production line. If there is any different between the furnished equipment in the customer’s factory and the equipment concerned in the contract, the users have the right to pass the inspection book to the legal department to claim for compensation to our company within goods warranty period.

please kindly click the play button to watch the video