Automatic 2 in 1 Can Filling Line Carbonated Drink Can Filler And Sealer Machine

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE,ISO |

| Model Number: | YDGF18-4 |

| Filling heads: | 18 |

|---|---|

| Sealing heads: | 4 |

| Filling material: | Carbonated drink |

| Applicable can: | Aluminum can or PET can |

| Automatic control: | PLC touch screen |

| Machine type: | 2 in 1 filling and sealing machine |

| Power: | 5.5KW |

| Driven type: | Electric |

| Guarantee time: | CE, ISO |

| Condition: | New |

| Voltage: | 380V, 3PHASE, 50HZ |

| After service: | Engineer available to overseas |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set/pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Blanket cloth or wooden case as machine need |

| Delivery Time: | 20-25 days |

| Payment Terms: | 30% T/T deposit, 70% before shipment. |

| Supply Ability: | 50 sets/month |

|

Detail Information |

|||

| Highlight: | bottling filling machine,aerosol can filling machine |

||

|---|---|---|---|

Product Description

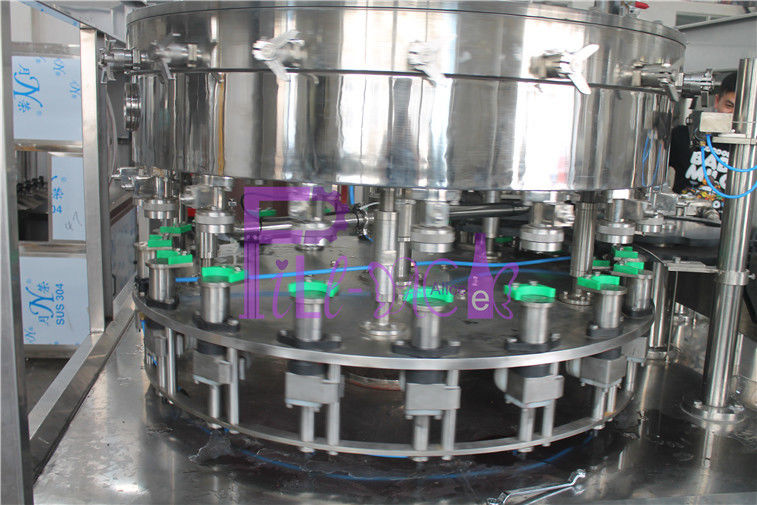

Automatic 2 in 1 Can Filling Line Carbonated Drink Can Filler And Sealer Machine

Quick Detail:

1. Capacity: 5000 Cans/H

2. Filling pressure: Balanced pressure

3. Can filling and sealing 2 in 1 machine, with 18 filling heads and 4 sealing heads

4. Main material: SUS304

5. Automatic with PLC touch screen, speed adjustable

6. For carbonated drink in PET can or aluminum can

Description:

The can filling line is used in production of carbonated drink of soft water, coca cola, carbonated drink, beer in aluminum can or PET can. Filling and sealing parts are integrated in one machine.

The machine is suitable for different can volume, with same can diameter different can height, no can change parts.

The most advanced technology is employed in the design. The filling is fast, the amount of liquid is accurately controlled and the dropping and leakage are avoided.

The whole machine is controlled by PLC with touch-screen as the human-machine interface, operation automatically, the speed is adjustable. The amount of the drinks in the storage tank can be controlled automatically. The filling and seaming will be stopped automatically when there is no can. When cans are cramped wrongly or when cans are not available, the machine can be stopped automatically.

The frequency changing technology is used to adjust the operation speed sleeplessly. The production capacity can be displayed digitally and can be adjusted conveniently.

Specifications:

| Model | YDGF18-4 |

| Capacity | 5000 cans/hour(500ml) |

| Filling head | 18 |

| Seaming head | 4 |

| Filling pressure | Balanced pressure |

| Filling valve | High quality special beer filling valve |

| Material | SUS304 |

| Can type | Aluminum can |

| Can size | 330ml,500ml with same can diameter |

| Conveyor | Include 2m can feeding conveyor and 4m can outlet conveyor |

| Filling precision | <+5MM |

| Air pressure | 0.5Mpa |

| Air consumption | 0.5m3/min |

| Power | 5.5 kw |

| Dimension(L*W*H) | 2000*1800*1900 mm |

| Weight | 3000 kg |