4000BPH Automatic PET Bottle Blowing Machine For Juice Bottle

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE. ISO9001 |

| Model Number: | CM-A4 |

| Condition: | New |

|---|---|

| Application: | PET bottle |

| Automatic: | Yes |

| Blow moulding type: | Stretch blow moulding |

| Voltage: | 380V 3 phase 50HZ / 60HZ / Customized |

| Warranty: | 1 year |

| After-sales service provided: | Engineers available to service machinery overseas |

| Bottle volume: | 100ml-2L |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set/pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Sea worthy package |

| Delivery Time: | 35-40 days after deposit receipt |

| Payment Terms: | TT / LC / |

| Supply Ability: | 1 set / month |

|

Detail Information |

|||

| High Light: | Bottle Making Machine,Blow Mold Machine |

||

|---|---|---|---|

Product Description

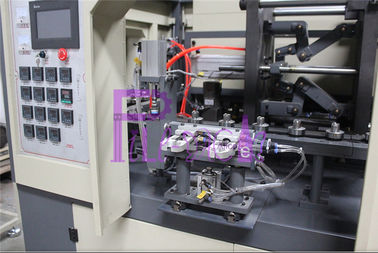

4000BPH Automatic Bottle Blowing Machine For Juice Bottle

Quick Detail:

1, Machine structure: Preform heating-blowing in one machine

2, Can be connected to production line

3, Automation: TOTALLY automatic

4, Bottle output: 4 pcs for one mould

5, Capacity: 4000BPH

6, Bottle type: PET bottles for filling juice and tea (hot filling)

7, Auxiliary machine needed: YES

Description:

Bottle blow molding system is used to blow plastic bottles in PET and PP. These bottles can be used to fill mineral water, juice, tea, carbonated water, and chemical liquid etc. So according to client's filling material, we can help to sculpt the bottle shapes before making the bottle moulds.

Applications and features:

- Widely used in food, beverage, dairy, cosmetic, medical, chemical industrial and etc;

- PLC control, electric parts are well-known brand;

- Develop different bottles for explore more market;

- High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

- High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure

- Easy operation and maintenance;

- Compact structure for the preform heating, blowing, and bottle forming are realized in one machine;

- All the movements of bottle blowing machine are driven by the air cylinder, no need the hydraulic oil and even no pollution.

- Auxiliary machines are needed during blowing including LP (Low pressure) air compressor, HP (High pressure) air compressor, air dryer, air filters, air tank, and mould chiller.

Connection diagram & electric parts:

![]()

![]()

Specifications:

| Main part: | ||

| Pneumatic part | Valve | SMC |

| Cylinder | ||

| Electric part | PLC | LG |

| Operating system | LG | |

| Relay | OMRON | |

| Infrared thermometer | America raytek | |

| Note | All of the electrical components adopts CE,UL,CCC approved international advanced high-tech product. | |

| Main parameter: | ||

| Model | CM-A4 | |

| Productivity | Depend on bottle design | 3200-4000PCS/H |

| Product type | Body diameter | 20mm-100mm |

| Height | 50mm-350mm | |

| Neck diameter | 15mm-38mm | |

| Mold | Cavity | 4cavities |

| Mold thick | 240mm | |

| Mold | 500*500mm | |

| Main machine power | Electrical source power | 380v 3Phase /220v 3Phase 50/60HZ |

| Rated Power | 49kw | |

| Really use power | 14kw | |

| Air source | LP air compressor | 1.6m3/min 1.0MPa 1set (15KW) |

| HP air compressor | 1.0m3/min 3.0MPa 2sets (each set 11KW) | |

| Air dryer | 2.0m3/min 3.0MPa 1set | |

| Cooling water | Cooling water | 15L/min |

| Size | L*W*H | 1900*1860*1930mm |

| Weight | 3600kg | |

| Auxiliary equipment(preform unscrambler) | L*W*H | 2000*950*2480mm |

| Weight | 250kg | |

| Resin available | PET | |

- Stable performance with advanced PLC.

- Automatic preform conveyer to save human cost.

- Introduce the FESTO air cylinder to avoid contamination and noise.

- Strong clamping force with high pressure and double crank links to lock the mould.

- Two ways of operating: automatic and manual.

- Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

- Easy for you to install,test and start up.

please kindly click the play button to watch the video