Full Automatic PET Bottle Blow Molding Machine Equipment 6 Cavity For 0.1 - 2L Bottle

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | FP-6000L |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SETS |

|---|---|

| Price: | 59,500USD |

| Packaging Details: | The machine is packed by wooden case |

| Delivery Time: | 15-20 Working Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 15 Sets Per Months |

|

Detail Information |

|||

| Number Of Cavities: | 6 | Function: | Blowing |

|---|---|---|---|

| Volume: | 0.1L-2L | Product Name: | Bottle Blowing Machine |

| Size: | 3700*1900*1800mm | Operation: | Automatic |

| Material: | PET | Weight: | 4000Kg |

| Theoretical Output (0.5L): | 6000BPH | ||

| Highlight: | Automatic PET Bottle Blow Molding Machine,6 Cavity PET Blow Molding Machine,PET 2L Bottle Blow Molding Machine |

||

Product Description

Product Description:

FP-6000L series is a fully automatic servo blow molding machine, It is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing mineral water bottles, soda bottles, cola bottles etc.

1. Preform feeding system: single-channel preform feeding, servo preform separation, fast and accurate, effectively solves the problem of wear between preforms and preforms.

2. Revolution system: special chains are used, driven by servo motors, so that the heating unit can move smoothly, locate quickly, and have low noise.

3. Heating system: The rotary blow molding machine is used for heating and conveying, which can reduce energy consumption and greatly improve the speed and quality of heating.

4. Mold system: adopts high-pressure mold clamping technology, no mold expansion phenomenon, and the mold clamping line is thin. The mold adopts a drawer structure, positioned on the mold back plate with four fixed tie rods, and can be easily replaced within half an hour.

5. Stretching and blowing system: the cycle time of first blowing and second blowing can be adjusted, and each tie rod can be adjusted individually according to different tube blanks and different bottle types of customers, with high flexibility.

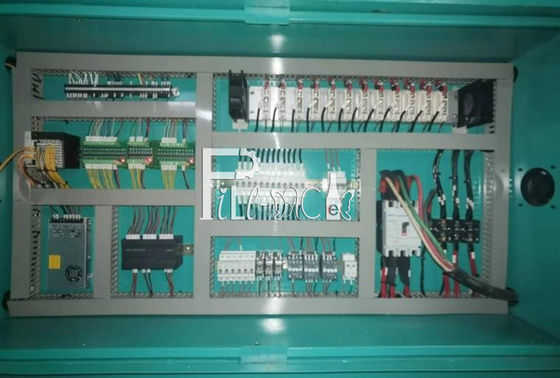

6. Electric control system: Pneumatic and electrical components are all international famous brands. The touch screen control system is easy to operate, has perfect monitoring and induction settings, has fault diagnosis function, automatic calculation report function, and grasps the production efficiency of each shift.

Features:

1. Produce bottle from 0.1L to 2L (6 cavity)

2. Output capacity: up to 2000BPH for 500ml

3. Advanced PLC control system with a user-friendly panel and time-control precision of PLC up to 0.01second

4. Equipped with special designed air storage unit

5. Using Infrared preform heater

6. Independent Temperature Control for different heating lamp to get ideal preform heating results

7. Heating lamps are adjustable in directions to suit various preforms.

8. Operated only by one person without special training.

9. Simple installation & start-up adjustment.

10. Waste rate of finished bottle is less than 0.2%

Technical Parameters:

| Model | FP-6000L | |

|

Container |

Product material | PET |

| Volume | 0.1L-2L | |

| Number of cavities | 6 | |

| Theoretical output (0.5L) | 6000BPH | |

| Applicable bottle Mouth Diameter | 32-50mm | |

| Applicable bottle body diameter | 60-100mm | |

| Applicable bottle height | 50-200mm | |

| Moulding | Max.mould plate Dimension(L x W) | 450x490mm |

| Max.mould thickness | 180mm | |

|

Machine size and weight |

Main machine (L x W x H) | 3700*1900*1800mm |

| Main machine weight | 4000Kg | |

| Preform unscrambler (L x W x H) | 4200*2000*2000mm | |

| Install Power-Using power | 22kw | |

Components

| Item | Description | Brand | Origin |

| 1 | Touch screen | XINJIE | China |

| 2 | Contactor | Schneider | France |

| 3 | Server system | XINJIE | China |

| 3 | Switching power supply | XINJIE | China |

| 4 | Heating module | SanREX | Japan |

| 5 | Guide rail | THK | Japan |

| 6 | Throttle valve | SMC | Japan |

| 8 | Upper and lower preform manipulator rotary cylinder | SMC | Japan |

| 9 | Upper and lower preform manipulator lifting cylinder | SMC | Japan |

Detailed photos:

![]() Preform loading

Preform loading

![]() Mould stretch blowing system

Mould stretch blowing system

![]() Electrical cabinet

Electrical cabinet

![]() Bottle outlet

Bottle outlet

![]()