Edible Oil Filling Machine Automatic Linear Plastic Bottle Jar Lubricant / Engine

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | HSG-4X/HSG-6X/HSG-8X/HSG-10X/HSG-12X |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 4000USD |

| Packaging Details: | Wooden case |

| Delivery Time: | 15 Working Days After Deposit |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 Sets Per Months |

|

Detail Information |

|||

| Filling Head: | 4/6/8/10/12 | Filling Range: | 3-5L |

|---|---|---|---|

| Bottle Diameter: | 30-120mm(Can Be Customized Wider) | Bottle Height: | 70-350mm(Can Be Customized Higher) |

| Work Pressure: | 0.4-0.8Mpa | Filling Material: | Oil, Paste |

| Machinery Capacity: | 1200BPH-5000BPH | Dimension(L*W*H): | 2050*1350*2200mm |

| Highlight: | 5000BPH Oil Filling Machine,Edible Oil Filling Machine Oil Production Equipment,5L Automatic Linear Oil Filling Machine |

||

Product Description

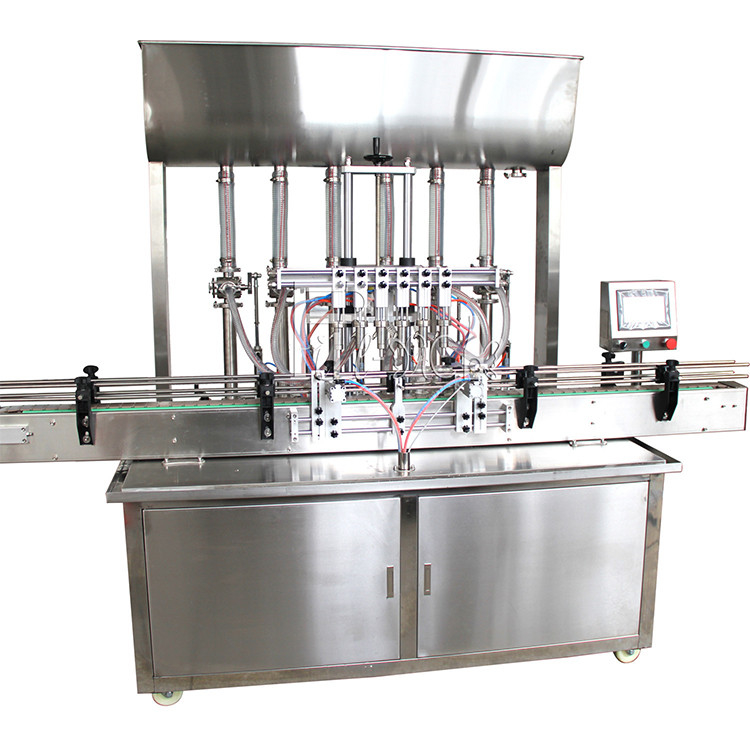

Automatic Linear Plastic Bottle Jar Lubricant / Engine / Cooking / Edible Oil Filling Machine Oil Production Equipment

General:

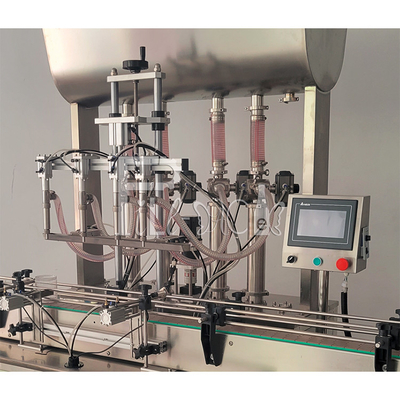

This type of machine is suitable for filling viscous, inviscid, and corrosive liquid. It's widely applied in plant oil, chemical liquid, and the daily chemical industry. It adopts linear type filling,electromechanical&instrucmental integration controlling.

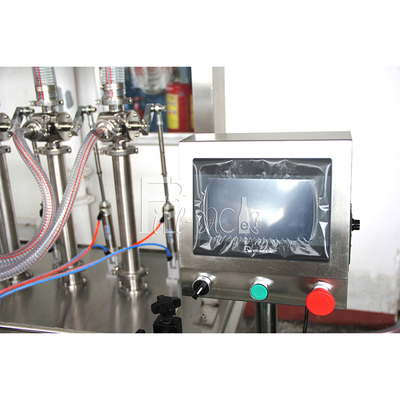

It's simple and rapid for changing the varieties with unique design and superior capability. Its appearance accords with the international machinery concept. PLC and touch screen control make it an intelligent protection function.

Main Features:

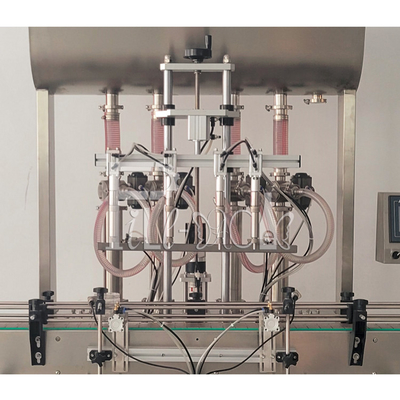

1. This filling machine is a fully automatic piston filling machine, suitable for filling various oils, such as lubricating oil, edible oil, etc;

2. Using stainless steel frame, easy to disassemble and clean, to meet the requirements of the food industry;

3. Human-machine interface, direct setting of filling volume, simple adjustment of filling volume and filling speed, touch screen operation display, beautiful appearance;

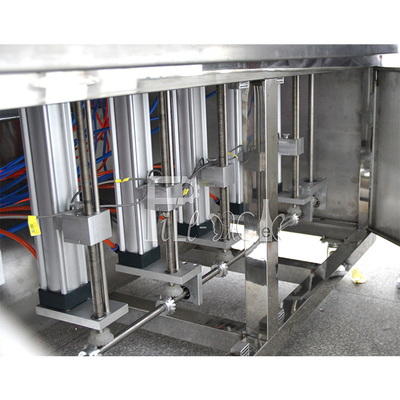

4. PLC program control, linear filling with frequency converter speed regulation;

5. High-precision liquid pump, accurate and reliable quantitative;

6. Using leak-proof filling nozzle, made of selected materials, anti-drip design, accurate filling, smooth discharge without clogging.

Parameters:

|

Model

|

HSG-4X

|

HSG-6X

|

HSG-8X

|

HSG-10X

|

HSG-12X

|

|

Filling head

|

4 heads

|

6 heads

|

8 heads

|

10 heads

|

12 heads

|

|

Filling range

|

10-100ML/20-300ML/50-500ML/100-1000ML

|

||||

|

Capacity

|

20-28pcs/min

|

30-40pcs/min

|

40-55pcs/min

|

50-70pcs/min

|

60-84pcs/min

|

|

Bottle diameter

|

30-120mm(Can be customized wider)

|

||||

|

Bottle height

|

70-350mm(Can be customized higher)

|

||||

|

Voltage

|

220V 1PH 50/60Hz

|

||||

|

Air consumption

|

1.6m³/min

|

2.4m³/min

|

3.2m³/min

|

4m³/min

|

4.8m³/min

|

|

Power

|

1.6KW

|

1.6KW

|

1.8KW

|

1.8KW

|

2.0KW

|

|

Work pressure

|

0.4-0.8Mpa

|

0.4-0.8Mpa

|

0.4-0.8Mpa

|

0.4-0.8Mpa

|

0.4-0.8Mpa

|

|

Filling accuracy

|

±1%

|

±1%

|

±1%

|

±1%

|

±1%

|

|

Weight

|

400KG

|

500KG

|

600KG

|

700KG

|

800KG

|

|

Size(mm)

|

2050*1350*2200

|

2500*1350*2200

|

|||

|

Body

|

Machine shell 201/Material contact part 304L

|

||||

Detailed Images

![]()

![]()

![]()