Monoblock Mineral Water Filling Capping Machine Plastic Bottle 6000BPH 18-18-6 Rinsing

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | CGF18-18-6 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SETS |

|---|---|

| Price: | 30723USD |

| Packaging Details: | Wooden Case Packing |

| Delivery Time: | 15-20 Working Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Bottle Volume: | 200ml-2000ml | Voltage: | 220V/380V |

|---|---|---|---|

| Machinery Capacity: | 6000BPH | Suitable Bottle Type: | PET Round Or Square Bottle |

| Function: | Full-automatic Rinsing-filling-capping | Material: | SUS304 |

| Cap Type: | Plastic Screw Cap | Application: | Purified Water, Mineral Water |

| Highlight: | Monoblock Mineral Water Filling Capping Machine,6000BPH Mineral Water Filling Capping Machine,18-18-6 Mineral Water Filling Machine |

||

Product Description

3 in 1 Monoblock 6000BPH 18-18-6 Plastic Bottle Mineral Water Production Line Rinsing Filling Capping Machine Equipment

General:

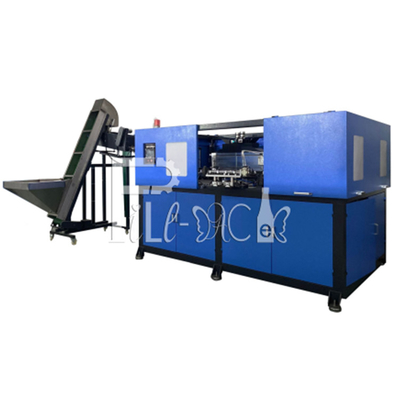

The water filling machine produced by Fillpack Machinery has good stability, easy operation and supports customization. It is Suitable for 200-2500ml PET bottles mineral water, drinking water, pure water etc. Different models water filler can satisfy various requirement of output from 1000BPH to 15000BPH.

The water filling machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine tofill various types of bottles. The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted.

2) The rotate plate is made of SUS AISI304, large flat toothed bearing.

3) The pressure mechanical valve is introduced the advanced foreign design with a fast filling speed, no hygiene corner pocket, a few sealing parts, and precise liquid level control. The whole valve is made of 304 stainless steel.

4) The filling system has a CIP circulation system to wash the pipeline and fake-cup used for cleaning filling valve. This system can clean the liquid pipe, liquid tank and filling valve etc. effectively.

5) This filling system has an automatic temperature control system.

6) The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve moves up and leaves the bottleneck when it finishes filling.

7) The liquid supply adopts the automatic pneumatic valve magnetic liquid-level switch to control the liquid tank automatically.

8) The motivation of the filler is derived from the driven system in the framework and passed by gear.

|

Model

|

CGF18-18-6 |

| Capacity (B/H) | 5000-7000(500ml) |

| Bottle size | Neck :φ50-100mm:Height:150-320mm |

| Water Pressure | 0.18-0.25Mpa |

| Water consumption(kg/h) | 1000 |

| Washing station | 18 |

| Loading-Dripping-discharge station | 2-2-2 |

| Filling precision | <+1MM |

| Air pressure | 0.5Mpa |

| Air consumption | 0.3m3/min |

| Power(kw) | 4 |

| Weight(kg) |

4000

|

| Dimension(L*W*H) | 2150*1750*2400 mm |

![]()

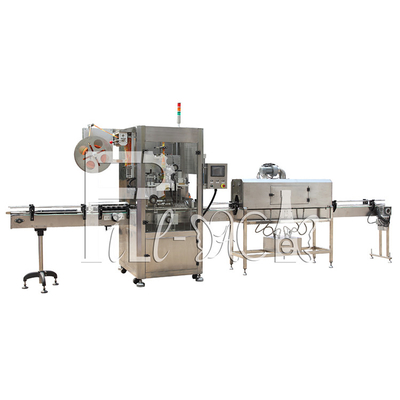

The special cutting system: adopting the whist and con-volute technology. The label cutting is flat, no burr.The label location set assures the sleeving veracity. Adopting model group design, module controlled; Achieve veracity and fast sleeving. With the good quality touching operation screen, achieving operation by finger, easy and shortcut. Within the flat width limitation, can be used to package objects in different shape, no matter round or square, can be applied on glass or plastic bottles.