Round Glass Jar Automatic Labeling Machine High Speed Wet Glue

Product Details:

| Place of Origin: | Jiangsu, China (Mainland) |

| Brand Name: | FillPack |

| Certification: | CE. ISO9001 |

| Model Number: | TB4000 |

| Condition: | New |

|---|---|

| Application: | Plastic bottle / Glass bottle round containers |

| Automation: | Automatic |

| Voltage: | Customize |

| Warranty: | 1 year |

| After-sales service provided: | Engineers available to service machinery overseas |

| Label type: | Paper label with glue on it |

| Operation mode: | Automatic / manual |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set/sets |

|---|---|

| Packaging Details: | Sea worthy package |

| Delivery Time: | 30 days after deposit receipt |

| Payment Terms: | TT/LC/Wertern union |

| Supply Ability: | 1 set/sets/month |

|

Detail Information |

|||

| Highlight: | industrial labeling systems,automatic labeling machine |

||

|---|---|---|---|

Product Description

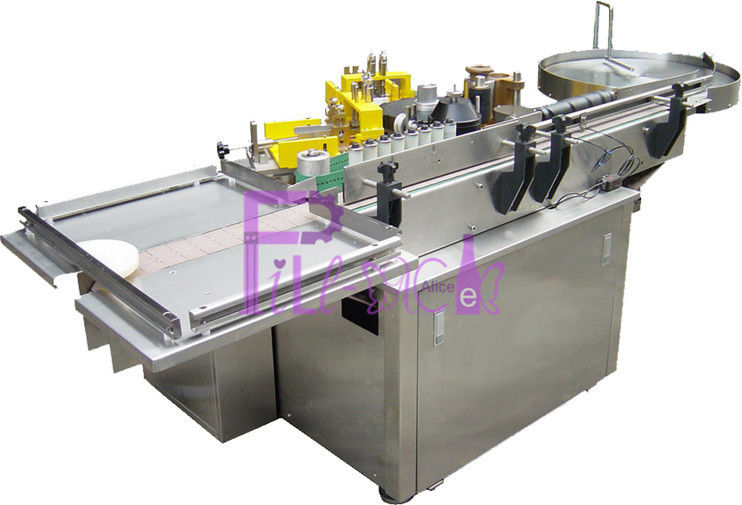

Round Glass Jar Automatic Labeling Machine High Speed Wet Glue

Quick Detail:

1, Bottle type: Round containers

2, Label type: Paper labels with glue on it

3, Connect to production line

4, Automation: Automatic labeling machine

5, Capacity: 4000BPH

Description:

It can do high speed automatic round labeling for round glass, PET bottles and pop-top cans in syrup, wine, drink, medical, cosmetics and other light industry.

Principle:

The working principle of the design of this machine is as the following: The fan shape rotating bar which sticks the label gets a little glue from the rubble wheel and rotates to the label transmission to get a piece of label adhered. And it continually rotates to the place of the sucking paper wheel with the vacuum, and the label is taken off by the doffing label claw. At the same time the label is transferred to the conveying paper belt with the vacuum. The label is conveyed into the sticking label area on the conveying paper belt with the sucking capability of the vacuum and is adhered on the bottle which is conveyed by the chains. It accomplishes the producing process by the circled actions.

Features:

1, This is a labeling machine which can label body, head and back. It has the characteristics, like reasonable structure, small area, the steel less and non-metallic surface. The whole machine adopts PLC control system, so that the whole stable, high-speed.

2, The machine adopts sensor detection, with accurate labeling and high accuracy. It also has no bottles no labeling, no labels automatic correction and detection, and any other functions

3, This machine adopts electromagnetic adjustable asynchronous motor and worm gear box as main drive, and equipped with pneumatic and electric control system. So that the machine can be used for continuously variable transmit. It can adjust the speed according to the entering bottles’ quantity, so that to suit the change of production, and ensure the safe running of machine.

4, It is easy to change the parts of the machine to suit different kinds of bottles and labels.

5, The body and parts are mainly using the anti-corrosion materials, like stainless steel, anti-corrosion alloy, plastic and other high corrosion resistance, casting, carbon steel, aluminum which have multi-layer anti-rust treatment.

Specifications:

| Dimension | 2050*1100*820 |

| Capacity | 4000BPH |

| Label length | 240mm |

| Label width | 30-80mm |

| Precision | +-1mm |

| Power source | According to customer's requirement |

| Power consumption | 1.5kw |

| Air consumption | 4-6kg |

| Machine weight | 550kg |

Configurations

| Item | Description of parts | Qua. | Remark & Brand |

| 1 | Main engine motor | 1 | Regal Beloit |

| 2 | Blower motor | 1 | Aideli |

| 3 | Transducer | 1 | Holip |

| 4 | Program controller | 1 | Mitsubishi |

| 5 | Photoelectric switch | 1 | Omron |

| 6 | Electrical components | 1 | Schneider |

| 7 | Solenoid valve, air cylinder, FRL | 1 | AIRTAC |

Competitive Advantage:

1. One year warranty for the whole system

2. Free equipment installation and debugging

3. After one year, we can help you to maintain the machine and the accessories are provided only one the cost price

4. Every 3 years, we can help to overhaul the machine free (Labor)

5. We can provide internship service and help you train the operator and mechanic

6. Free production technology and process configuration

7. We can help you to design the production line, workshop and provide turn-key project