2L Mineral Water Filling Machine For PET Bottle Rinsing Filling Capping Machine Plant

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | QS-12 CG-12 FXZ-1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 sets |

|---|---|

| Price: | 18775USD |

| Packaging Details: | wooden case |

| Delivery Time: | 30-35 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Bottle Volume: | 200-2000MLZhangjiagang, China | Machinery Capacity: | 2000BPH |

|---|---|---|---|

| Applicable Bottle: | D∮50-100mm,H 50-350mm | Voltage: | 380V 50Hz |

| Applicable Bottle Type: | Plastic Bottle/PET Bottle | Material: | SUS304 |

| Function: | Auto Rinsing-filling-capping | Whole Line Power: | 30.5KW |

| Highlight: | 2000BPH PET Mineral Water Filling Machine,SUS304 PET Mineral Water Filling Machine,Rinsing Filling Capping Machine Plant |

||

Product Description

0-2L Drinking water filling machine for PET Bottle Mineral Water Production Line Rinsing Filling Capping Machine plant

Part I water treatment-1500LPH mono block RO system

![]()

Parameters:

| Items | Name | Specifications and model | Material | Brand&Origin | Unit | Qty. |

| I | Raw water lifting unit | |||||

| 1 | Level controller | ST-70AB | assembly | PRADAR | suit | 1 |

| 2 | Raw water pump | CDL4-12/2.2kw | SUS304 | NanFang | set | 1 |

| II | Multimillionaire filter | assembly | FILLPACK | |||

| 1 | Multimillionaire filter tank | Φ500*1700MM | FRP | FILLPACK | set | 1 |

| 2 | Central tube, Up and below distribution | Matching | ABS | RUNXIN | suit | 1 |

| 3 | Manual operation valve | TMF56D | assembly | RUNXIN | set | 1 |

| 4 | Quartz sand | NO. 1-4, Filling height 1000mm | assembly | NingBo | KG | 300 |

| III | Active carbon filter | assembly | FILLPACK | |||

| 1 | Filter tank | Φ500*1700MM | FRP | FILLPACK | set | 1 |

| 2 | Central tube, Up and below distribution | Matching | ABS | RUNXIN | suit | 1 |

| 3 | Manual operation valve | TMF56D | assembly | RUNXIN | set | 1 |

| 4 | Activated Carbon | 10-24MU | Shell | Chengde | kg | 100 |

| IV | Cartridge filter | assembly | FILLPACK | |||

| 1 | Cartridge filter | 30INCH *5 | SUS304 | FILLPACK | suit | 1 |

| 2 | PP cotton | 30INCH / 5 um | polypropylene | FILLPACK | pcs | 5 |

| 5 | Pressure gauge | 0-0.1MPa | SUS304 | YYST | pcs | 1 |

| VI | RO system | |||||

| 1 | High pressure pump | CDL4-12/2.2kw | SUS304 | NANFANG | set | 1 |

| 2 | RO pressure vessel | 4040*2 | SUS304 | BONA | pcs | 3 |

| 3 | RO membrane | 4040-HR | poly amide | LANXING | pcs | 6 |

| 4 | Water inlet solenoid valve | DN32/AC220V | BRASS | YONGCHUAN | pc | 1 |

| 5 | Washing solenoid valve | DN25/AC220V | BRASS | YONGCHUAN | PC | 1 |

| 6 | Pressure gauge | 0-0.6MP/0-3MPA | SUS304 | YYST | pcs | 4 |

| 7 | High low pressure switch | 0.1-3MPA | SUS304 | BD | pcs | 1 |

| 8 | Conductivity meter for produced water | CCT3320 | assembly | CREATEC | suit | 1 |

| 9 | Flow-meter for produced water | Rotor type 20G | acrylic | YYST | PCs | 1 |

| 10 | Flow-meter for salinity water | Rotor type 20G | acrylic | YYST | PCs | 1 |

| 11 | Main frame of RO | L2700*W800*H1600MM | SUS304 | FILLPACK | suit | 1 |

| VII | Connecting pipe | |||||

| 1 | Tubing/fittings/valves | DN32/DN25/DN20, etc | UPVC/GB | XieYu/China | suit | 1 |

| VIII | Pure water tank | |||||

| 1 | Level controller | ST-70AB | assembly | PRADAR | suit | 1 |

| IX | Electrical system | |||||

| 1 | control cabinet | BD-4.0 | SUS304 | FILLPACK | suit | 1 |

| 2 | Programmer | CCT3320 | matching | CREATEC | suit | 1 |

| 3 | Air switch | Matching | assembly | CHNT | suit | 1 |

| 4 | AC cont actor | suit | 2 | |||

| 5 | Thermal relay | suit | 2 | |||

| 6 | Intermediate relay | suit | 1 | |||

| 7 | Button / switch | suit | 1 | |||

| 8 | wire | suit | 1 | |||

| 9 | accessories | suit | 1 |

UV sterilizer

| Model | 55W |

| Suitable for water treatment systems | RO-1500/RO-2000 |

| Power | 55W |

| Overall dimension | 910*63*63 |

| Inlet/outlet size | 3/4” |

| Connector type | BSP Male |

| Max operating pressure | 0.8MPa |

| Ultraviolet intensity | 30mj/cm2 |

| Material of operating cavity | 304 |

| UV lamp service life | 9000 hours |

Part II Drinking water bottling line

Rotary bottle washer

![]()

Principle:

This washer is developed on the basis of digesting and absorbing advanced technology introducing from abroad and is with international advanced level. It is mainly used for rising for 1st hand PET or glass bottles.It is advanced in construction , steadily in performance, safe in operation , easy in maintenance high in production efficiency, and the speed can be regulated infinitively. The rinser is the ideal choice for drink factories of small and middle size.

The bottles will be taken into rinser by conveyor, the dia plate will turn each bottle to be caught by spring clamp, with driven energy of motor, the spring clamps will go forward a circle along main axis, the bottles will be reversed 180°,bottle mouths will be facing to floor, and at the meantime, spray water value will be open and clean pressure water will spray inside bottles, with the water fall down, dirty inside bottles will be taken away. Then the cleaned bottle will be turned 180°again and sent into next machine station.The whole machine is made of SUS304. The spring clamp is by Italian design, can be slightly adjustable according to bottle neck size difference and can protect bottle neck. And water spray system is from American, make sure water spray averagely. Easy for clean and maintenance.

Parameters:

Rising heads: 12 pcs

Capacity: 0-3000BPH (each bottle rinsing time 4s)

Power: 0.92KW

Dimension: 1050*950*1700mm

Weight: 700KG

Applicable bottle: D∮50-100mm,H 50-350mm

Normal pressure filler

![]()

Principle:

This filler is developed on the basis of digesting and absorbing advanced technology introducing from abroad and is with international advanced level. It is mainly used for filling non carbonated drink. It is advanced in construction , steadily in performance, safe in operation , easy in maintenance high in production efficiency, and the speed can be regulated infinitively. The filler is the ideal choice for drink factories of small and middle size.

The bottles will be taken into filler by conveyor, the dia plate will turn each bottle to be caught by holding clap, with driven energy of motor, the holding claps will go up and down as main axis, when clap hold bottle, it will go up to press bottle mouth closely to filling head, at the meantime, filling value open and start to fill, when the bottle mouth leave the filling head, filling stop.

The whole machine is made of SUS304. The filling head is spring type without dead angel, no dripping. Easy for clean and maintenance. The holding clap model is suitable for all bottles with same bottle neck, it is easy for change bottle shape and volumes.

Parameters:

Filling heads: 12 pcs

Power: 1.1KW

Dimension: 1100*1050*1850mm

Weight: 800KG

Screw cap capping machine

![]()

Principle:

The machine is used for capping for plastic screw caps, it includes auto cap loader and capping system 2 parts. Workers put bulk qty caps into cap loader, the cap loader will unscramble caps automatically and bring caps down in cap rail and then to capping head. Cap loader can hold more than 200pcs of caps each time, it will be convenient for adding caps often. When capping head catch cap, it will go down to bottle mouth and finish capping.

The capping head is by Italian magnetic technique, it will protect caps not to be destroyed. The capping correctness will be 99%. The opposite caps will be deleted automatically. The capping head is an separate part. Change cap is only need to change capping head, easy for change and operation. The whole machine is made from SUS304, long shelf time.

Parameters:

Capping head: 1 pc

Power: 1.1KW

Dimension: 1000*850*2000mm

Weight: 600KG

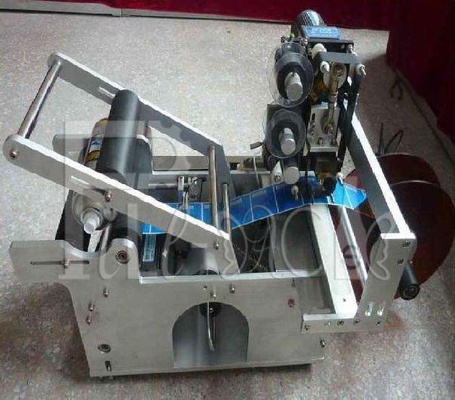

Part III Semi-auto adhesive labeling machine for round bottles with code printer

![]()

Worker load bottles manually on bottle loading position, then press labeling rack down to bottlePrinciple:

surface, then labeling roll will rotate and leave the label to bottle surface, labeling, pressing can be done at the same time; High labeling quality, no bubble, no decline; Machine have a range to be adjusted for different size bottle.

Characters:

■Applicable for glass bottle and PET bottles in round shape. Machine need special order if the bottle is in particular shapes

■Coder can be added if need

Parameters:

■Machine Size: 650(L)×450(W)×550(H)mm

■Output Speed: 20-50pcs/min

■Bottle diameter range (mm): 10-150mm

■Suitable Label Height: 15-120mm

■Suitable label Length: 15-315mm

■Labeling precision: ±1mm

■Labeling roll inner diameter: 76mm

■Labeling roll outer diameter: 250mm

■Weight: 35kg

■Power Supply: 110V 0.12KW 50/60HZ

Part IV:Semi-auto shrink-wrapping packing machine:

![]()

PE Film wrapping -cutting unit

Working principle:

Shrink packing is one of the developed packing method in current market, it uses shrink film wrapping outside the products, after heating, the film will shrink, it will show the goods better and it will improve sales of the goods, increase value of the goods. At the meantime, the goods after packing will be prevented from moisture and pollution, it will buffer the outside conflict, especially when the goods is easy to break, it will stop the scatter. Workers put bottles as arranged group requirement, we will give group arrangement helping device for easy arrangement, after bottle arrangement, worker press start to indicated the wrapping device to wrap PE film on the group of bottles, then film cutting, group transmission and final shrinkage will be done by machine automatically;

Characters:

1,Packing method:

(1) 350/500/550/600ML: large package:4×6,4×5 ; Small package: 3×4,3×5 four type of package

method.(2) 1L/1.5L/2L/2.5L: Large package:3×3,3×4; small package: 2×2,2×3 four type of

package.

2,Regarding can package, we suggest adopt to package with tray , pack steadily.

3,packing speed:0-5pcs/min

4,package material:PE thermos shrinkage film width(200-550mm),thickness(0.07-0.12mm)

Technical data:

● Max wrapping size: 350*550*380mm

● Max sealing length: 550mm

● Working air pressure requirement: 0.1m³/min

● Power source: AC220-240V 50/60HZ

● Power: 40W

● Dimension: 1100*1100*2050mm

● Weight: 230kg

Pack shrink tunnel unit:

1.The control panel can adjust the speed and heating temperature, and the leakage protection switch plays a protective role.

2. The bottled items are placed on the stainless steel mesh belt, which runs very smoothly and has a good shrinkage effect.

3. Special mechanical structure design, out shell more nice and maintaining more convenient.

4. Temperature control part, it use developed intelligent apparatus , it will improve the temperature

accuracy.

5. All electrical apparatus use branded machine, it will make sure the whole machine quality.

6. The machine is suitable for all kinds of films.

7. Double-wind cycling fan machine and super wind-volume cooling system to ensure the temperature in shrinkage tunnel evenly.

Technical data:

● Tunnel inner size: 1500*600*400mm

● Shrinkage Power source: AC 380 V 3PH

● Shrinkage Power: 20KW

● Blower: 1set 60W

● Conveyor motor: AC 220V /120W

● Conveyor speed: 0-10m/min

● Max loading: 30Kg

● Dimension: 2500*800*1450mm

● Weight: 230kg

The general specification of the whole unit

● Pneumatic component 1set

● Speed adjustment motor 1 set

● Stainless iron wing type heating tube

● Stainless steel convey belt

● Thermos sealing knife cast aluminum heating board has the character as even temperature, long life, is our special product.

● Whole machine outer plastic-sprayed, the frame is made of high-quality carbon steel, main part adopt to stainless steel.