4000BPH Monoblock Mineral Water Filling Capping Production Line 500ML Bottle Rinsing

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | CGF12-12-4 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SETS |

|---|---|

| Price: | 42653USD |

| Packaging Details: | Wooden Case Packing |

| Delivery Time: | 15-20 Working Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Bottle Volume: | 200ml-2000ml | Machinery Capacity: | 4000BPH |

|---|---|---|---|

| Suitable Bottle Type: | PET Round Or Square Bottle | Function: | Full-automatic Rinsing-filling-capping |

| Voltage: | 220V/380V 50Hz | Material: | SUS304 |

| Cap Type: | Plastic Screw Cap | Suitable For: | Non-carbonated Water |

| Highlight: | Water Bottle Rinsing Filling Capping Machine,4000BPH Water Bottle Filling Capping Machine,500ML Water Bottle Filling Capping Machine |

||

Product Description

4000BPH Monoblock 500ML-2L Plastic Bottle Mineral Water Production Line / Plant Rinsing Filling Capping Equipment

General:

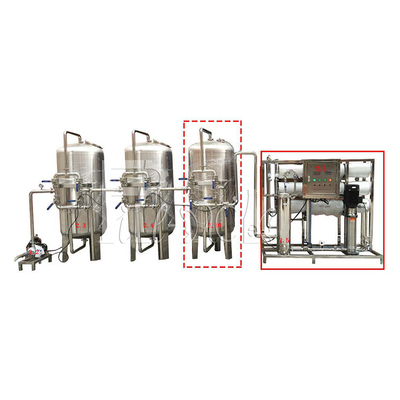

The water production line is divided into purified water and mineral water production lines. It starts with the purification of raw water, enters the water filling machine after disinfection, then labels and inkjet codes, and finally packag and cases.

The water filling machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine tofill various types of bottles. The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted.

|

Model

|

CGF12-12-4 |

| Capacity(B/H)(330ml) | 3000-4000 |

| Bottle size | Neck:φ20-50mm;Height:150-320mm |

| Water pressure | 0.18-0.25Mpa |

| Water consumption(kg/h) | 1000 |

| Washing station | 2 |

| Dripping station | 2 |

| Filling precision | <+1MM |

| Air pressure |

0.4Mpa

|

| Air consumption (m³/min) | 0.3 |

| Power(kw) | 5 |

| Weight(kg) | 2500 |

| Dimension(L*W*H)(mm) | 2100*1700* 2400 |