Full Automatic Shrink Sleeve Labeling Machine Double Head For Body With Steam Shrink

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | TB150-2 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SETS |

|---|---|

| Price: | 19344USD |

| Packaging Details: | Wooden Case Packing |

| Delivery Time: | 15-20 Working Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Labeling Speed: | 300BPM(On The Base Label Length :55mm) | Applicable Label Length: | 30-250mm |

|---|---|---|---|

| Thickness Of Label: | 0.04mm | Applicable Diameter Of Bottle Body: | 28mm ~120mm |

| Applicable Inner Diameter Of Label Rod: | 5''~10'' | Power: | 6KW |

| Function: | Neck-Body Sleeve Labeling Unit | Input Voltage: | ∮3, 380/220 VAC |

| Dimension: | 3200*1200*2070 | Weight: | 300KG |

| High Light: | Shrink Sleeve Labeling Machine,6KW Shrink Sleeve Labeling Machine,250mm Shrink Sleeve Labeling Machine |

||

Product Description

Full Automatic Double Head Shrink Sleeve Labeling Machine Plant For Both Body / Neck Labels With Steam Shrink System

General:

Whole machine frame is made out of stainless steel SUS304. The frame is simple, beautiful, waterproof and not rust. It is easy for cleaning. The special cutting system: adopting the whist and con-volute technology. The label cutting is flat, no burr.The label location set assures the sleeving veracity. Adopting model group design, module controlled; Achieve veracity and fast sleeving.With the good quality touching operation screen, achieving operation by finger, easy and shortcut. It is a high automatic packingmachine. Just one person handles, easy operation. Easy to change packing material, the change over of the mould can be easily done by hand without any tools.Within the flat width limitation, can be used to package objects in different shape, no matter round orsquare, can be applied on glass or plastic bottles. Higher safely and stability for operation and saving time of manpower.

Specifications:

1)TB-150-2 Sleeve Labeling Machine is custom built to meet the exacting demands of manufacturers and suppliers. It can be used stand alone or integrated in-line and matching filling equipment speeds.

2)It is built upon a framework of seam welded, food grade stainless steel section. This solid foundation keeps movement and vibration to an absolute minimum to ensure consistent, accurate labeling.

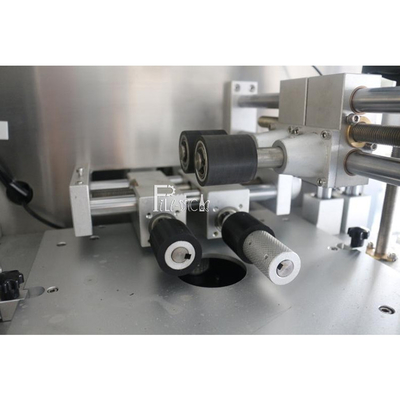

3)Unit cutter head plane design in China which apply to the container of ∮30 mm—∮130 mm. you never need to change or debug it.It also has unique light touch human-machine screen,that means,auto search original location as well as safety and convenience which is ahead of other congener products.

4)Double shrinking label feed plane, reasonable height which is convenience to fix the label; micro-computer auto figure which avoid enactment and adjustment. You only need to press it lightly ,the label will detect and locate automatically.The change of label is quick and convenience, besides,the cut place is absolutely exact.

5) The newly designed cutter servo motor which speed is high ,action is exact,the cut is in order and the shrinking is beautiful.This design cooperate with the label synchronized location structure enable the precision of cut location within 1mm.

|

No.

|

Item

|

Technical data

|

|

|

1

|

Import Power

|

6.0KW

|

|

|

2

|

Component power

|

Label Infeeding Servo Motor

|

800W

|

|

3

|

|

Label Infeeding Servo Drive

|

800W

|

|

4

|

|

Cutting Head Servo Motor

|

800W

|

|

5

|

Import Voltage

|

∮3, 380/220 VAC

|

|

|

6

|

Capacity(production speed)

|

300BPM

(On the base label length :55mm) |

|

|

7

|

Dimension of Host Machine (mm)

|

3200*1200*2070

|

|

|

8

|

Applicable Diameter Container (mm)

|

φ28 mm ~ φ120 mm

|

|

|

9

|

Applicable Label Length (mm)

|

30~250 mm

|

|

|

10

|

Applicable Thickness Label (mm)

|

0.04mm

|

|

|

11

|

Applicable Inner Diameter of Paper Tube

|

76mm~125mm

|

|

|

Name

|

Function

|

|

Material offering group

|

Offer motor for label carrier

|

|

Shelf group

|

Install volume label device

|

|

Platform elevating group

|

Adjust the height of host automatically according to the bottle shapes

|

|

Brush-off group

|

Brushing the cut-ted label on the bottle

|

|

Cutter group

|

Cutting off the labels which are sent to Center guide pin

|

|

Cutter controlling group

|

Control the cutter operational site

|

|

The back drive group

|

Offer motor for label of center guide pin

|

|

The front drive adjusting group

|

Grasping the center guide pin

|

|

Frame of Electric eye group

|

Adjust the best cutting position of the label

|

|

Electric eye of bottle lighting detecting group

|

Adjust the sleeve labeling position of bottle body

|

|

Hairbrush group

|

Brush the label which cannot sleeve properly to the right place

|

|

Bottle positioning group

|

Make bottle stable, control sleeve labeling position

|

|

Center guide pin group

|

Make volume label distracted for transfer and cut easily

|

|

Bottle entering screw bolts

|

Separate bottle on equal distance in order to sleeve labeling accurately

|

|

PLC

|

Panasonic

|

Japan

|

|

Touch Screen

|

WEINVIEW

|

Taiwan

|

|

High-speed Optical Fiber Sensor*2

|

Panasonic

|

Japan

|

|

Photoelectric Sensor*4

|

Panasonic

|

Japan

|

|

Photoelectric Sensor*4

|

Panasonic

|

Japan

|

|

Label Infeeding Servo Motor*2

|

Panasonic

|

Japan

|

|

Label Infeeding Servo Drive*2

|

Panasonic

|

Japan

|

|

Cutting Head Servo Motor*2

|

Panasonic

|

Japan

|

|

Cutting Head Servo Drive*2

|

Panasonic

|

Japan

|

|

Bottle Separation Frequency Converter*4

|

Delta

|

Taiwan

|

|

Bottle Conveyor Frequency Converter

|

Delta

|

Taiwan

|

|

Conveyor Frequency Converter

|

Delta

|

Taiwan

|

|

Label Feeder Frequency Converter

|

Delta

|

Taiwan

|

|

Switching Power Supply

|

Schneider

|

France

|

|

AC Contactor

|

Schneider

|

France

|

|

Circuit-breaker

|

Schneider

|

France

|

|

Intermediate Relay*13

|

Schneider

|

France

|

Detailed Images

![]()

![]()

![]()

![]()

![]()

Auxiliary machine

![]()

![]()

Heat Steam Shrink tunnel