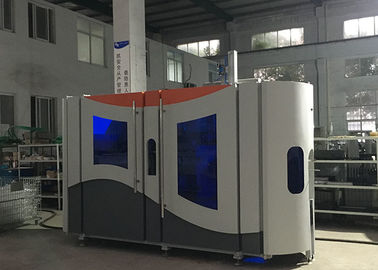

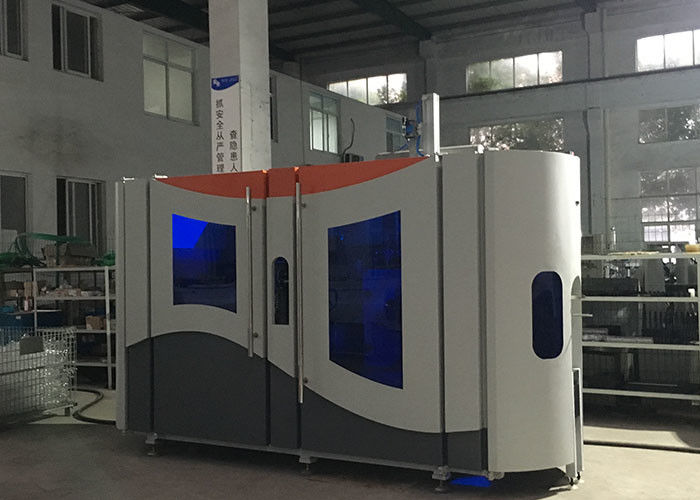

Pure Drink / Drinking / Drinkable Water Bottle Blow Moulding / Molder / Molding Machine / Equipment / Plant / System

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE. ISO9001 |

| Model Number: | FP-6000DS |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set/pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Sea worthy package |

| Delivery Time: | 35-40 days after deposit receipt |

| Payment Terms: | L/C, D/A, D/P, T/T, , MoneyGram |

| Supply Ability: | 1 set / month |

|

Detail Information |

|||

| Max. Bottle Volume: | 2L(100-2000ml) | Weight: | 3500Kg |

|---|---|---|---|

| Dimension: | 3900*900*2500mm | Output: | 9500-10000BPH |

| Cavitiy: | 6Cavities | Power: | 51kw |

| Condition: | New | Application: | PET Bottle |

| Automatic: | Yes | Blow Moulding Type: | Stretch Blow Moulding |

| Voltage: | 380V/220V 3 Phase 50HZ / 60HZ / Customized | Warranty: | 1 Year |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | ||

| Highlight: | Bottle Injection Machine,Bottle Making Machine |

||

Product Description

Automatic servo linear 6 cavity blow molding line

>>> Product Introduction:

FP-6000DS 6 cavity Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Our new design PET bottle machine with below high-tech can save 130000kwh electric one year for customer compare with normal linear four cavity blowing machine.

>>> Product Features:

1. Auxiliary Machine To operate this PET blowing machine, it also need some auxiliary machines. such as air compressor, air filter, air dryer, chiller and so on. we will equip the auxiliary machine according to your need.

Specifications:

|

Model

|

FP-6000DS

|

||

|

Container

|

Applicable Preform Height/Neck

|

<330mm/25mm,28mm,30mm

|

|

|

Applicable Bottle Volume/Height/Diameter

|

Max.2Liter/Max.328mm/Max.105mm

|

||

|

Theoretical output

|

9500-10000PCS/H(based on 500ml)

|

||

|

Applicable bottle body diameter

|

20-92mm

|

||

|

Applicable bottle height

|

50-350mm

|

||

|

Electric consumption

|

Install power

|

51kw 380v 3Phase /220v 3Phase 50/60HZ

|

|

|

Heating oven power/Heating Oven operating power

|

46kw/26kw

|

||

|

Machine size and weight

|

Machine size

|

3900*900*2500mm

|

|

|

Main machine weight

|

3500Kg

|

||

|

Sorting machine/Loader

|

2000*1500*1500mm/3000*1000*1500mm

|

||

|

Blowing Main machin

|

3600*1600*2300mm

|

||

|

Blowing mould

|

6 cavity

|

||

![]()