3 L 1500b / H Automatic Blowing Machine For Pet Bottle , PLC Control

Product Details:

| Place of Origin: | ZhangJiaGang,JiangSu,China |

| Brand Name: | FILL PACK |

| Certification: | CE. ISO9001 |

| Model Number: | FP-6000-2 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set/pcs |

|---|---|

| Price: | USD $62,000-63,000/Set |

| Packaging Details: | the Plastic Bottle Blowing Machine is packed by wooden case. |

| Delivery Time: | within 30 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, , MoneyGram |

| Supply Ability: | 5 Set/Sets per month |

|

Detail Information |

|||

| Capacity: | 1300-1600bph | Cavity: | 2 Cavities |

|---|---|---|---|

| Contractor: | Schneider | PLC: | DELTA |

| Key Word: | Plastic Bottle Blowing Machine | Application: | PET Plastic |

| Warranty: | 12 Month | Material: | Stainless Steel |

| Electricity: | Mistubishi | Voltage: | 220V/380V/custmerized |

| Highlight: | Bottle Injection Machine,Bottle Making Machine |

||

Product Description

3 L 1500b / H Automatic Blowing Machine For Pet Bottle , PLC Control

Product Description

Machine specification:

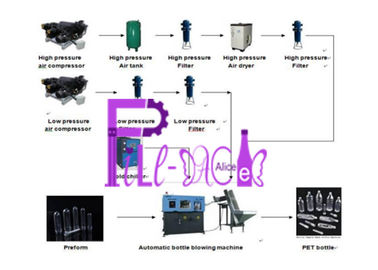

FP-6000-2 Automatic Plastic Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 100ml to 6000ml, wide application for blowing mineral water bottles, soda bottles,

cola bottles..etc

1. Adopts advanced microcomputer control system, stable performance, the conveyor automatically send embryo;

2, Use infrared heating lamps, penetrating power strong, embryo heated while rotation, orbital revolution, heating uniformity, rapid and reliable;

3, Light tube in heating area, reflector width and height can be adjusted to suit the different structure preform heating, and automatic exhaust temperature device in order to ensure constant temperature of the drying tunnel;

4, Each machine has a safety self-locking device, when a processes have problem, the program will automatically switch to a safe state;

5, All the action drive by the cylinder, do not use pumps, with no pollution, low noise;

6, Gas way design divide action and air blowing into three parts, action to meet the needs of the different pressure of the blowing, action;

2,Features:

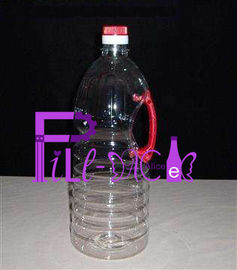

1. Produce bottle from 0.1L to 6L (2cavity)

2. Output capacity up to 1500 for 6L using two-cavity blow mould

3. Advanced PLC control system with a user-friendly panel and time-control precision of PLC up to 0.01second

4. Equipped with special designed air storage unit

5. Using Infrared preform heater

6. Independent Temperature Control for different heating lamp to get ideal preform heating results

7. Heating lamps are adjustable in directions to suit various preforms.

8. Operated only by one person without special training.

9. Simple installation & startup adjustment.

10. Waste rate of finished bottle is less than 0.2%

Main parameter of the machine:

| Main paremeter | ||

| Model | FP-6000-2 | |

| Container | Production material | PET |

| Volume | 0.1-6L | |

| Theoretical output | 1300-1600PCS/H(6L) | |

| Applicable bottle body diameter | 20-200mm | |

| Applicable bottle neck | 25-58mm | |

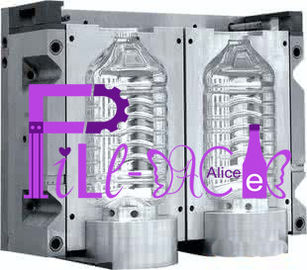

| Moulding | Max stretching distance | 350*460mm |

| Max. mould thickness | 305mm | |

| Machine size and weight | Main machine(L*W*H) | 2250*2150*2200mm |

| Main machine weight | 5500kg | |

| Preform unscrambler (L*W*H) | 2100*1000*2650mm | |

| Heater weight | 450kg | |

| Install Power-Using power | 66kw-36kw | |

| N/M | item name | BRAND | ORIGINAL PLACE |

| 1 | PLC controller | DELTA | Taiwan |

| 2 | TOUCH SCREEN | DELTA | TAIWAN |

| 3 | Pneumatic components | FESTO | GERMANY |

| 4 | Pneumatic components | AIRTAC | TAIWAN |

| 5 | Photoelectric signal switching | OMRON | JAPAN |

| 6 | control button | OMRON | JAPAN |

| 7 | AIR FILTER | DELTA | TAIWAN |

| 8 | Electromagnetic valve | PMC | KOREA |

| 9 | High pressure muffler silencer | SMC | JAPAN |

Detailed Image

![]()

![]()

![]()

![]()

![]()

![]()

Packing & Delivery

![]()

![]()

![]()

Our Service

Customer's service:

1. FILL-PACK company can provide turn-key project for you, only you have any idea to start beverage factory plant.

2. FILL-PACK company have professional design team, our engineer can draw bottle samples and flow chart ofworkshop for you .

3. FILL-PACK company give you the best quotation for all kinds of beverage production, only you can tell me whichkind of drink you want to product, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass,etc

After service:

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General manual book/maintenance book

please kindly click the play button to watch the video