Carbonated Water Juice Wine PET Plastic Glass 3 In 1 Monobloc Bottle Filling Machine / Equipment / Line / Plant / System

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE & ISO & TUV & SGS |

| Model Number: | DCGFG18-18-6 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 20000-50000USD |

| Packaging Details: | Wooden Case Package |

| Delivery Time: | 30 Working Days After Receiving Your Deposit Payment |

| Payment Terms: | L/C, D/A, D/P, T/T, , MoneyGram |

| Supply Ability: | 20 sets/month |

|

Detail Information |

|||

| Dimension(L*W*H): | 2360*1770*2700 Mm | Weight: | 3800KG |

|---|---|---|---|

| Power: | 5KW | Packaging Type: | Crown Glass Bottle |

| Capacity: | 3000-4000bph | Voltage: | 380V/220V 50HZ |

| Highlight: | soft drink making machine,drink production line |

||

Product Description

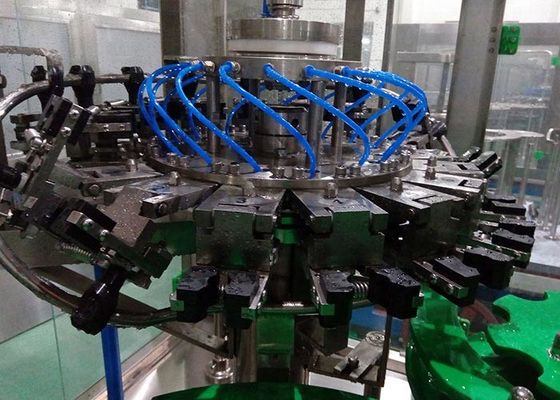

Description of DCGFG18-18-6 Crown Cap Glass Bottle Filling machine

>>>Our machine have so many characteristics:

★1, The system is simple: the integral table board is adopted, the structure is rigid, easy to wash and clean, easy to maintain, and the maintenance of the machine is more convenient and simple.

★2, Convenient and rapid change of bottle type: The quick-opening structure is adopted for the change parts, and the quick and convenient change of bottle type is suitable for PET bottles of various specifications.

★2, Convenient and rapid change of bottle type: The quick-opening structure is adopted for the change parts, and the quick and convenient change of bottle type is suitable for PET bottles of various specifications.

★3.This kind of Glass Bottle Making Machine combines washing,filling and rotary capping functions in one unit.It is a fully automatic and high efficiency liquid packing equipment.

★4.Glass Bottle Making Machine is suitable for packing beverage containing gas.Glass Bottle Making Machine 's performance is as following all parts,for instance, filling valve, which directly contact medium are made of stainless steel or harmless material. So it conforms to the requirements of Food sanitation. Sealing parts are made of heat-proofing rubber, in order to meet the technique requirements of users to sterilization at high temperature.

★4.Glass Bottle Making Machine is suitable for packing beverage containing gas.Glass Bottle Making Machine 's performance is as following all parts,for instance, filling valve, which directly contact medium are made of stainless steel or harmless material. So it conforms to the requirements of Food sanitation. Sealing parts are made of heat-proofing rubber, in order to meet the technique requirements of users to sterilization at high temperature.

|

Teachnical parameters of DCGFG18-18-6

|

||||||

|

Filling precision

|

≤+/-1mm(liquid level)

|

|||||

|

Filling pressure

|

≤0.4MPa

|

|||||

|

Glass bottle specification

|

(Bottle diameter)50-100mm (Height)170-320mm

|

|||||

|

Suitable cap shape

|

Glass or other material screw cap

|

|||||

|

Filling temperature

|

0℃—5℃

|

|||||

|

Cleaning pressure

|

0.2-0.25MPa

|

|||||

|

|

||||||

|

Our family of glass bottle carbonated filling machine

There's always one suitable for you

|

||||||

|

Model

|

Rinsing filling capping heads

|

Capacity(BPH)

|

Power(kw)

|

Weight(Kg)

|

Dimension

(mm)

|

|

|

DCGFG12-12-4

|

12/12/4

|

1000-2000

|

4.4

|

2800

|

|

|

|

DCGFG18-18-6

|

18/18/6

|

3000-4000

|

5

|

3800

|

2360*1770*2700

|

|

|

DCGFG24-24-8

|

24/24/8

|

6000-7000

|

6

|

5000

|

3200*1900*2300

|

|

|

DCGFG32-32-10

|

32/32/10

|

8000-10000

|

8

|

6000

|

4300*2000*2300

|

|

|

DCGFG40-40-12

|

40/40/12

|

10000-12000

|

10

|

9000

|

4500*3500*2300

|

|

|

|

||||||

|

If you need plastic bottle carbonated filling machines, please check them on our website or contact the sales consultant directly. Please find the contact information at contact us.

|

||||||

![]()

![]()

Cap feeder

The cover is conveyed to the cover manager through the upper cover device, and the back cover of the cover enters the cover channel through the reverse cover recovery device in an open upward position. When the cover opens downward, the cover enters the cover manager through the reverse cover recovery device and returns to the cover manager, thus ensuring that the cover from the cover manager passes through the cover channel in the correct position. Enter the lid disinfector and disinfect the inside of the lid.

Want to Know more details about this product