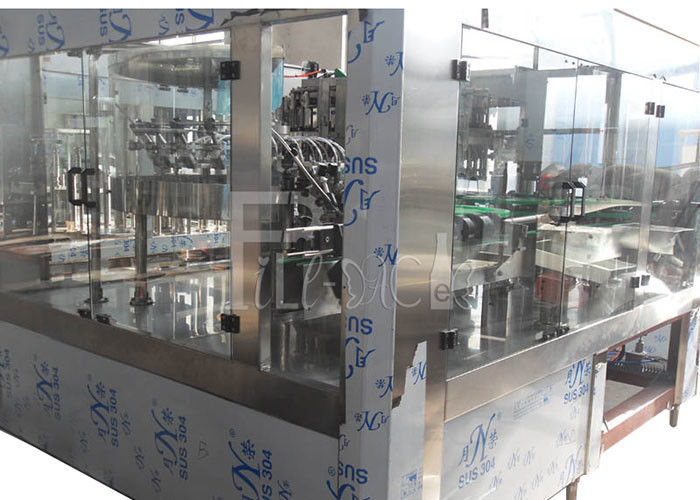

PET Plastic Glass 3 In 1 Monobloc Soda Drink Beverage Water Bottle Production Machine / Equipment / Plant / Syste

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE & ISO & TUV & SGS |

| Model Number: | DCGFG40-40-12 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 20000-50000USD |

| Packaging Details: | Wooden Case Package |

| Delivery Time: | 30 Working Days After Receiving Your Deposit Payment |

| Payment Terms: | L/C, D/A, D/P, T/T, , MoneyGram |

| Supply Ability: | 20 sets/month |

|

Detail Information |

|||

| Dimension(L*W*H): | 4500*3500*2300mm | Weight: | 9000KG |

|---|---|---|---|

| Power: | 10KW | Packaging Type: | Glass |

| Application: | Beverage | Capacity: | 10000-12000 Bph |

| Highlight: | soft drink making machine,drink production line |

||

Product Description

Bottle Washing

1) The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

2) The rinser is driven by driving system positioned inside machine frame via gear transmission.

3) Rinser using high-strength stainless steel bottles of spring-loaded folders, to ensure a stable reversal of the glass bottles. The nozzle is a plum-like structure can wash every corner of the side wall and bottom to make the bottle clean.

1) Adopted Germany anti-corrosion non-maintaining bearing that can reduce the pollution of filling to the environment.

2) The rotate plate is made of SUS AISI304, large flat toothed bearing.

3) The pressure mechanical valve is introduced the advanced foreign design with a fast filling speed, no hygiene corner pocket, a few sealing parts, and precise liquid level control. The whole valve is made of 304 stainless steel.

4) The filling system has a CIP circulation system to wash the pipeline. This system can clean the liquid pipe, liquid tank and filling valve etc. effectively.

|

Teachnical parameters of DCGFG40-40-12

|

||||||

|

Filling precision

|

≤+/-1mm(liquid level)

|

|||||

|

Filling pressure

|

≤0.4MPa

|

|||||

|

Glass bottle specification

|

(Bottle diameter)50-100mm (Height)170-320mm

|

|||||

|

Suitable cap shape

|

Glass or other material screw cap

|

|||||

|

Filling temperature

|

0℃—5℃

|

|||||

|

Cleaning pressure

|

0.2-0.25MPa

|

|||||

|

|

||||||

|

Our family of glass bottle carbonated filling machine

There's always one suitable for you

|

||||||

|

Model

|

Rinsing filling capping heads

|

Capacity(BPH)

|

Power(kw)

|

Weight(Kg)

|

Dimension

(mm)

|

|

|

DCGFG12-12-4

|

12/12/4

|

1000-2000

|

4.4

|

2800

|

|

|

|

DCGFG18-18-6

|

18/18/6

|

3000-4000

|

5

|

3800

|

2360*1770*2700

|

|

|

DCGFG24-24-8

|

24/24/8

|

6000-7000

|

6

|

5000

|

3200*1900*2300

|

|

|

DCGFG32-32-10

|

32/32/10

|

8000-10000

|

8

|

6000

|

4300*2000*2300

|

|

|

DCGFG40-40-12

|

40/40/12

|

10000-12000

|

10

|

9000

|

4500*3500*2300

|

|

|

|

||||||

|

If you need plastic bottle carbonated filling machines, please check them on our website or contact the sales consultant directly. Please find the contact information at contact us.

|

||||||

Auxiliary equipment:

Blow molding system

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Drink Mixing Machine

1/Wide range of uses - The system can handle a wide range of products such as carbonated drinks, juice drinks, etc.

2/Easy power adjustment - easy adjustment of mixing ratio without having to replace parts.

3/Structural Hygiene - All parts in contact with fluids are of high quality stainless steel, all tanks are equipped with CIP ball for easy cleaning.

4/Accurate mixing accuracy - product mixing accuracy G ≤ 2%