Two Cavity 0.1-2L PET Bottle Blowing Machine For Juice Processing Line

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE. ISO9001 |

| Model Number: | DY-2000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set/pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Sea worthy package |

| Delivery Time: | 35-40 days after deposit receipt |

| Payment Terms: | TT / LC / |

| Supply Ability: | 1 set / month |

|

Detail Information |

|||

| Application: | PET Bottle | Blow Moulding Type: | Stretch Blow Moulding |

|---|---|---|---|

| Automatic Grade: | Automatic | Bottle Volume: | 100ml-2L |

| Capacity: | 2000BPH | Warranty: | 1 Year |

| Highlight: | Bottle Injection Machine,Bottle Making Machine |

||

Product Description

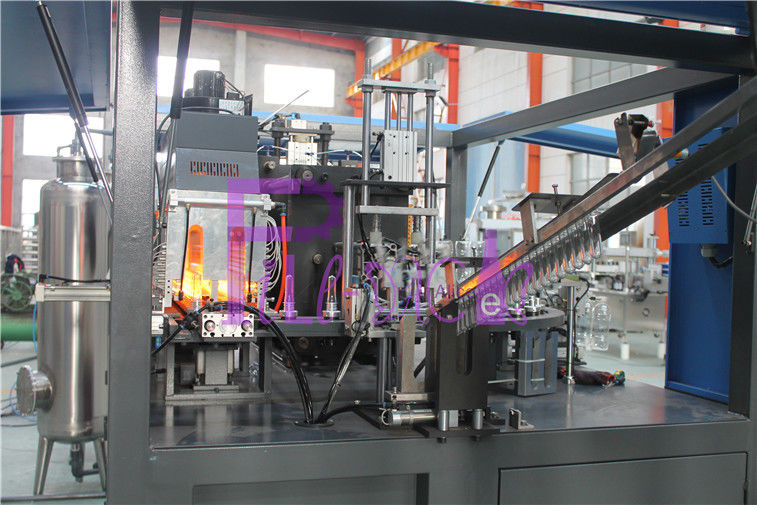

Two Cavity 0.1-2L PET Bottle Blowing Machine For Juice Processing Line

Quick Detail:

1, Machine structure: Preform heating-blowing in one machine

2, Can be automatically connected to production line

3, Automation: TOTALLY automatic

4, Bottle output: 2000BPH

5, Driven manner: electric and pneumatic

6, Bottle type: PET bottles

7, Auxiliary machine needed: YES

Description:

Two Cavity bottle blowing machine is used to blow plastic bottles. Two cavity means there are two pieces of bottles out in one mould. These bottles can be used to fill mineral water, juice, tea, carbonated water, and chemical liquid etc. So according to client's filling material, we can help to sculpt the bottle shapes before making the bottle moulds.

Applications and features:

- Widely used in food, beverage, dairy, cosmetic, medical, chemical industrial and etc;

- Produce bottle from 0.1 to 2L (2 cavity);

- Output capacity up to 2000-2500 for 500ml;

- Advanced PLC control system with a user-friendly panel and time-control precision of PLC up to 0.01s;

- Equiped with special designed air storage unit;

- Using infrared preform heater;

- Independent temperature control for different heating lamp to get ideal preform heating results;

- Heating lamps are adjustable in directions to suit various preforms;

- Operated only by one person without special training;

- Simple installation & startup adjustment;

- Waste rate of finished bottle is less than 0.2%.

Connection diagram & electric parts:

![]()

![]()

Specifications:

| Model | DY-2000 | |

| Container | Product material | PET |

| Volume | 0.1L-2L | |

| Theoretical output | 2000-2500PCS/H (500ml) | |

| Applicable bottle body diameter | 20-92mm | |

| Applicabe bottle height | 50-350mm | |

| Moulding | Max. mould plate dimention (L*W) | 450*490mm |

| Max. mould thickness | 180mm | |

| Machine size and weight | Main machine (L*W*H) | 2500*1650*1850mm |

| Main machine weight | 3200kg | |

| Preform unscrambler (L*W*H) | 2000*950*2480mm | |

| Heater weight | 250kg | |

| Install power - using power | 18kw | |

- Adopts advanced microcomputer control system, stable performance, the conveyor automatically send preform;

- Use infrared heating lamps, penetrating power strong, preform heated while rotation, orbital revolution, heating uniformity, rapid and reliable;

- Light tube in heating area, reflector width and height can be adjusted to suit the different structure preform heating, and automatic exhaust temperature device in order to ensure constant temperature of the drying tunnel;

- Each machine has a safety self-locking device, when a processes have problem, te program will automatically switch to a safe state;

- All the action drive by the cylnder, do not use pumos, with no pollution and low noise;

- Gas way design divide action and air blowing into three parts, action to meet the needs of the different pressure of the blowing, action;

- Cooling system to achieve the desired cooling effect; H- the bottle scrap rate less than 0.2%.

please kindly click the play button to watch the video