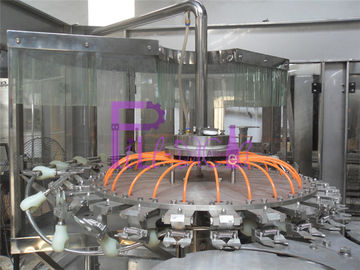

Rice Wine Glass Bottle Filler Machine Industrial 3 - in - 1 Hot Filling Line

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE & ISO & TUV & SGS |

| Model Number: | RCGF24-24-8 |

| Color: | Silver Gray |

|---|---|

| Control: | PLC Control With Touch Screen |

| Processing: | Japan & Germany |

| Suitable Bottle Size: | Glass bottle |

| Cap Style: | Metal Caps |

| Capacity: | 6000-8000BPH |

| Electrical Brand: | Mitsubishi, OMRON, SIEMENS |

| Warranty: | 1 Year for Spare Parts |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Case Package |

| Delivery Time: | 30 Working Days After Receiving Your Deposit Payment |

| Payment Terms: | TT & L/C |

| Supply Ability: | 20 sets/month |

|

Detail Information |

|||

| Highlight: | liquid filler equipment,water bottling equipment |

||

|---|---|---|---|

Product Description

Rice Wine Glass Bottle Filler Machine Industrial 3 - In - 1 Hot Filling Line

Quick Detail:

Machine structure: 3 in 1 filling machine

Filling type: hot filling machine

Bottle type: glass bottle

Cap type: twist off caps

Filling material: Flavored juice, tea, rice wine

Description:

1. Integrate washing, filling and capping in one unit

2. Can be used for different kinds of fruit juices and tea hot drink production. With only a few parts changed, the machine can also be used for mineral water filling.

3. The advanced micro-negative pressure filling technology is used in this machine to make the filling is quick, steady and accurate.

4. Meet all the technical requirements for hot drink filling below 95°c. All filling valves and beverage conducting pipes can be cleaned. And the automatic washing interface CIP is designed in the machine before capping.

5. It can use constant power to screw capping the plastic caps. The human machine interface is the touch screen. The most advanced PLC control and frequency changing technologies are used in this machine.

Specifications:

| Model | RCGF12-12-4 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 | RCGF40-40-12 |

| Production(B/H)(500ml) | 4000-5000 | 6000-8000 | 8000-12000 | 12000-15000 | 16000-20000 |

| Bottle standard | Neck: φ50-100mm; Height: 150-320mm | ||||

| Water pressure of washing bottle | 0.18-0.25Mpa | ||||

| Water consumption for washing bottle(kg/h) | 1300 | 2000 | 3000 | 4000 | 5000 |

| Spraying position | 4 | 7 | 10 | 14 | 18 |

| Dripping bottle position | 3 | 5 | 8 | 10 | 15 |

| Filing precision | +5MM | ||||

| Gas source pressure | 0.4Mpa | ||||

| Gas consumption(m³/min) | 0.3 | 0.4 | 0.5 | 0.7 | 0.8 |

| Total power(kw) | 4.2 | 4.5 | 5 | 6.2 | 7.8 |

| Total weight(T) | 2 | 2.5 | 3 | 4 | 6 |

| Dimension (L*W*H)(mm) | 2100*1600*2100 | 2500*1750*2100 | 2700*2100*2100 | 3500*2100*2100 | 3800*2200*2200 |

Competitive Advantage:

1. One year warranty for the whole system

2. Free equipment installation and debugging

3. After one year, we can help you to maintain the machine and the accessories are provided only one the cost price

4. Every 3 years, we can help to overhaul the machine free (Labor)

5. We can provide internship service and help you train the operator and mechanic

6. Free production technology and process configuration

7. We can help you to design the production line, workshop and provide turn-key project

Market Distribution:

| Market | Revenue(Previous Year) | Total Revenue (%) |

| Africa | confidential | 40% |

| Middle east | confidential | 15% |

| America | confidential | 5% |

| Euro | confidential | 4% |

| Middle Aisa | confidential | 3% |

| South-east Asia | confidential | 3% |

| Domestic | confidential | 30% |

please kindly click the play button to watch the video