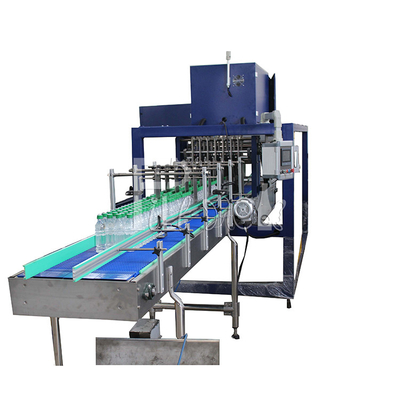

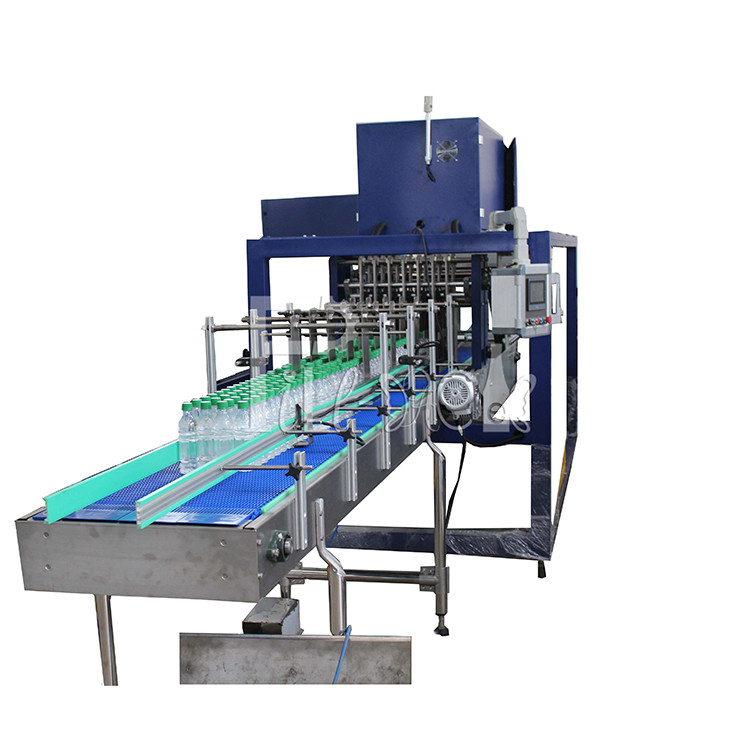

Fully Automatic Linear Shrink Wrapper For Plastic Bottle Packing Equipment With Printed Films

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | MBC200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | 43000USD |

| Packaging Details: | Wooden case |

| Delivery Time: | 25-30 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Shrinkage Film Material: | PE | Suggested Shrinkage Film Thickness: | 0.07-0.15mm |

|---|---|---|---|

| Shrinkage Tunnel Max Temperature: | 180 - 220° Adjustable | Max Output Per Minute: | 20-25 Bags/min |

| Power For Heating Shrink Part: | 31KW | Power For Tunnel: | 4KW |

| Standard Voltage: | 380V 3Phase 50HZ | Whole Plant Size: | 14150*1500*2170mm |

| Compressed Air Consumption: | 0.3M3/min; 0.6-0.8mpa | Weight: | 1500kg |

| Highlight: | Fully Automatic Linear Shrink Wrapper,Linear Shrink Wrapper For plastic Bottle,25 bags/min Automatic Linear Shrink Wrapper |

||

Product Description

Fully Automatic Linear Shrink Wrapper For Bottle Packing Machine Warpping Equipment With Printed Films

Product instruction

● Simple appearance, beautiful, novel structure, unique, easy maintenance.

● large-screen screen, the user interface LCD display in English.

● Pneumatic expansion support film roll, changing film quickly and quickly, for film only about two minutes.

● Film tension transmission, even formation, cutting film control precision, incision and tidy.

● advanced servo control technology to maintain accurate synchronization of the agencies, transmission and reliable.

● heating box structure is reasonable, thermal insulation, high temperature control accuracy.

● Supporting French Schneider, TAIWAN AIRTAC, South Korea AUTONICS ; the world's most advanced control components, well-equipped, condition and stability.

● mechanical transmission parts using heat-treated stainless steel or carbon steel and other materials; surface spraying excellent quality, the whole rust-proof performance

● All the electric and gas control are in line with the latest international application standards (CE standard)

● When the power cut with artificial rotation conveyor device, it is easy to heat the product inside the channel out

● Support both transparent blank film and printing printed film wrapping packing.

Technical parameter:

| Shrinkage film material | PE |

| Max output per minute | 20-25 bags/min |

| Suggested shrinkage film thickness | 0.07-0.15mm |

| Shrinkage tunnel max temperature | 180 - 220° adjustable |

| Power for Heating shrink part | 31KW |

| Power for tunnel | 4KW |

|

Bottle inlet and film wrapping part |

L6300×W1500×H2100mm |

|

Shrink tunnel part(include roller conveyor) |

7850×1100×2170mm |

|

Compressed air consumption |

0.3M3/min; 0.6-0.8mpa |

|

Inlet bottle convey belt width |

966m |

Recommended package type:

(1)350/500ML bottles package: 4×6, 4×5; 550/600ML bottles package: 3×4, 3×5.

(2)1L/1.5L bottles package: 3×3, 3×4; 2L/2.5L bottles package: 2×2, 2×3.

(3)Regarding tin cans, we suggest adopt to package with carton tray, pack steadily.

Remark: Minimum support package size: 200*150*100mm;

Maximum support package size: 420*300*330mm;

Main structure and produce process

Main structure: the equipment is made of bottle feeding conveyor part, Bottles sorting part, Film feeding and wrapping part, shrink heating tunnel, fan chilling part, roller conveyor output part and electric control system, pneumatic control parts and so on.

Produce process:

MBC200 High-speed heat-shrink packaging machine (printed film type) is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online, and the collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding. The bottle plate is arranged in a powerful manner, servo-controlled pushing bottles and wrapping into packages, heating channels shrinking, cold air cooling and shaping and other mechanisms to complete the entire packaging process.

Specification details:

| No | Name | Specification | Qty | Brand | Origin |

| 1 | 10.4 inch key operation screen | 1set | Schneider | France | |

| 2 | Servo motor | 5sets | Schneider | France | |

| 3 | servo controller | 5sets | Schneider | France | |

| 4 |

Photoelectric detection, induction switch |

5sets | AUTONICS | South Korea | |

| 5 | Pneumatic components | AIRTAC | TAIWAN | ||

| 6 | Electrical components | Schneider | France | ||

| 7 | Main transmission bearings | Harbin | |||

| Main operating bearing | |||||

| 8 | Linear bearing | Harbin | |||

| 9 | Reduction drive | 4sets | AUTONICS | South Korea | |

| 10 | PCC control system selection | Schneider | France | ||

| A | Servo motor | 5sets | Schneider | France | |

| B | servo controller | 5sets | Schneider | France | |

| C | 5.7 "push-button operation panel | PP41 type | 1piece | Schneider | France |

| D | Bus interface | RS-232,CAN | 1piece | Schneider | France |

| E | Input and output modules | 6piece | Schneider | France | |

| 11 |

Conveyor chain belt (engineering plastics) (Including all kinds of sprocket, guide wheel, pad) with a high-intensity, high wear-resistant and so on |

DuPont Corporation |

America | ||

| 12 |

Heating pipe (spiral heat dissipation form) |

24pieces | |||

| 13 | Heating fan 1.1kw | 2sets | |||

| 14 | High insulation (Class H) | 2sets | |||

| 15 | Heating mesh with high-quality stainless steel material 924mm × 500mm |