2400BPH PET Bottle Blowing Molding Machine Full Automatic 2 Cavity 500ml - 2L

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | FP-2000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SETS |

|---|---|

| Price: | 16725USD |

| Packaging Details: | Wooden Case Packing |

| Delivery Time: | 15-20 Working Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Volume: | 0.1L-2L | Theoretical Output (0.5L): | 2400BPH |

|---|---|---|---|

| Applicable Bottle Body Diameter: | 20-92mm | Applicable Bottle Height: | 50-350mm |

| Max.mould Plate Dimension(L X W): | 450x490mm | Max.mould Thickness: | 180mm |

| Main Machine (L X W X H): | 1956*1670*2030mm | Install Power-Using Power: | 18KW |

| Highlight: | PET Bottle Blowing Molding Machine,Bottle Blowing Molding Machine 2400BPH,500ml Bottle Blowing Molding Machine |

||

Product Description

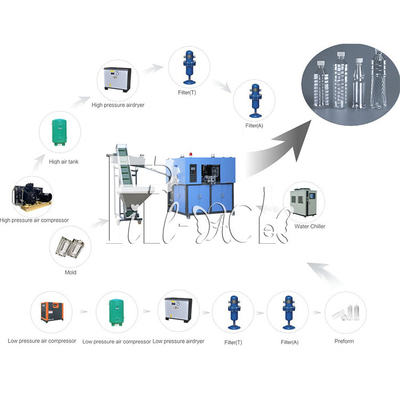

2400BPH Full Automatic 2 Cavity 500ml-2L PET / Plastic Bottle Blow Molding Machine Plant For Pure Water Filling Line

FP-2000 series are the most stable two-step automatic blowing machines. It has 2 cavity, the mould can be customized as clients need, 500ml, 1200ml, 1500ml, 1800ml, 2000ml. It can blow bottles in shapes: Carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type. We can make the moulds as clients' various needs. We can do the test report of water quality, design various shape of bottles, we can do the bottle blowing test first before making the final decision.

Settings

1. Using the new clamping system with double crank four tie-bars,the cross balanced fixed glide.

2. The seal,the stretch use the parallel bars union and combined design,which is advantageous to the product formation.

3. The advanced air course design,the single-channel or single-channel air admission;low pressure for clamping,sealing and stretching;the high pressre for blowing the bottle.

4. PLC control system, the operaton is easy controled .

5. With infrared heating,controllable constant pressure control,frequency conversion,thus achieves blows the perfect bottle.

6. The height of the UV light tubes in preform heater is adjustable. Also, there is setting to keep the temperature in the heater, exhaust extra heat.

7. Every movement, every components have safety treatment, any progress happens accident, the machine will be in safety mode.

8. Safe, dependable, special design of valves, easy to do maintainance.

Features

1. Conveying preforms automatically with conveyor.

2. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater.

3. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

4. No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

5. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

6. Strong clamping force with high pressure and double crank links to lock the mold.

7. Two ways of operating: Automatic and manual.

8. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

9. Contamination is avoided for the bottle body.

Technique Parameter

|

Model

|

FP-2000

|

|

|

Container |

Product material

|

PET

|

|

Volume

|

0.1L-2L

|

|

|

Theoretical output (0.5L)

|

2300BPH(all servo)

2000BPH (normal model) |

|

|

Applicable bottle body diameter

|

20-92mm

|

|

|

Applicable bottle height

|

50-350mm

|

|

|

Moulding |

Max.mould plate Dimension(L x W)

|

450x490mm

|

|

Max.mould thickness

|

180mm

|

|

|

Machine size and weight |

Main machine (L x W x H)

|

1956*1670*2030mm (normal)

2161*2070*2075mm (servo) |

|

Main machine weight

|

3200Kg

|

|

|

Preform unscrambler (L x W x H)

|

2000*950*2480mm

|

|

|

Install Power-Using power

|

18kw

|

|

|

Additional Servo power |

Add power for preform transport servo

|

3kw

|

|

Add power for mold clamping servo

|

3kw

|

|

|

Add power for stretch servo

|

3kw

|

|

Details:

![]()

![]()

![]()

![]()

Application:

![]()