Low Noise 1500ML Full Automatic water bottle blowing machine with 6 Cavity

Product Details:

| Place of Origin: | ZhangJiangGang,JiangSu,China |

| Brand Name: | FILL PACK |

| Certification: | CE. ISO9001 |

| Model Number: | FP-6000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set/pcs |

|---|---|

| Price: | USD $64,000-66,000 |

| Packaging Details: | the water bottle blowing machine is packed by wooden case. |

| Delivery Time: | within 30 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, , MoneyGram |

| Supply Ability: | 5 Set/Sets per month |

|

Detail Information |

|||

| Capacity: | 6000bph | Cavity: | 6cavities |

|---|---|---|---|

| Key Word: | Water Bottle Blowing Machine | Condition: | New |

| Application: | Bottle | Plastic Processed: | PET |

| Blow Moulding Type: | Stretch Blow Moulding | Voltage: | 380v 3Phase/220v 3Phase 50/60HZ |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Warranty: | 1 Year |

| Weight: | 1050KG | Dimension(L*W*H): | 2650mm X 2050mm X 2200mm |

| Automatic: | Yes | Power(W): | 72kw |

| Valve: | FESTO (Germany) | Configuration: | All The Components Are Selected With International Famous Brand. |

| Highlight: | Bottle Injection Machine,Bottle Making Machine |

||

Product Description

Low Noise 1500ML Full Automatic water bottle blowing machine with 6 Cavity

Product Description

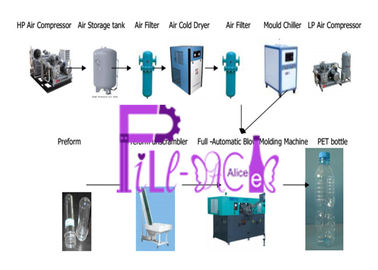

water bottle blowing machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle, oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

![]()

![]()

![]()

Technique Parameter of water bottle blowing machine:

| Componets: | ||

| Part | Brand | Origin |

| Pneumatic components | AIRTAC | Taiwan |

| Turning cylinder | FESTO | German |

| High pressure air blowing valve | PARK | USA |

| Low pressure operation valve | PMC | Korea |

| PLC | DELTA | Taiwan |

| Touch screen | DELTA | Taiwan |

| High pressure muffler | SMC | Japan |

| Oily water separator | AIRTAC | Taiwan |

| Photoelectric switch | AUTONICS | Korea |

| Switching power | WM | Taiwan |

| Air switch | TAIAN | Taiwan |

| Relay | IDEC | Japan |

| Finger cylinder | MINDMAN | Taiwan |

| Note | All of the electrical components adopts CE,UL,CCC approved international advanced high-tech product. | |

| Main parameter: | ||

| Model | FP-6000 | |

| Productivity | Depend on bottle design | 5000-5500 PCS/H |

| Product type | Body diameter | 20mm-100mm |

| Height | 50mm-350mm | |

| Neck diameter | 15mm-38mm | |

| Mold | Cavity | 6 cavities |

| Mold thick | 200mm | |

| Mold | 800*800mm | |

| Main machine power | Electrical source power | 380v 3Phase /220v 3Phase 50/60HZ |

| Rated Power | 40kw | |

| Really use power | 20kw | |

| Cooling water | Cooling water | 20L/min |

| Size | L*W*H | 2808*1958*1920mm |

| Weight | 4500kg | |

| Auxiliary equipment(preform unscrambler) | L*W*H | 2000*950*2480mm |

| Weight | 250kg | |

| Resin available | PET | |

Features of main body:

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity in variable.

5). High safeties with security automatic-locking device in each mechanica laction, whichwill make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Introduce the FESTO air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Safe,reliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

11). Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

12). Ideal cooling system make the finished bottles without any flaws.

13). Easy for you to install,test and start up.

14). Low rejection rate: less than 0.2 percent.

Detailed Images

![]()

![]()

![]()

![]()

![]()

![]()

Packing & Delivery

1. the water bottle blowing machine is packed by wooden case.

2. The delivery date of water bottle blowing machine is within 30 days after payment.

Our Service

Customer's service:

1. FILL-PACK company can provide turn-key project for you, only you have any idea to start beverage factory plant.

2. FILL-PACK company have professional design team, our engineer can draw bottle samples and flow chart ofworkshop for you .

3. FILL-PACK company give you the best quotation for all kinds of beverage production, only you can tell me whichkind of drink you want to product, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass,etc

After service:

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General manual book/maintenance book

3. After one year guarantee, the seller provides payable spare parts and technician’s VISITING maintenance service.

please kindly click the play button to watch the video