2L 2000BPH Carbonated Bottle Blow Molding Machine Double Cavity Automatic

Product Details:

| Place of Origin: | ZhangJiaGang,JiangSu,China |

| Brand Name: | FILL PACK |

| Certification: | CE. ISO9001 |

| Model Number: | FP-2000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set/pcs |

|---|---|

| Price: | USD $26,000-27,000/Set |

| Packaging Details: | the carbonated bottle blowing machine is packed by wooden case. |

| Delivery Time: | 30 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, , MoneyGram |

| Supply Ability: | 5Set/Sets per month |

|

Detail Information |

|||

| Cavity: | 2 Cavities | Capacity: | 2000bph |

|---|---|---|---|

| Volume: | 0-2 L | Automatic: | Yes |

| Model: | FP-2000 | Application: | PET Plastic |

| Shaps Type: | All Kind Shaps | Weight: | Customized |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Contain: | Water, CSD, Juice, Tea, Alcohol Drinks, Oils, Cosmetics,etc. |

| Warranty: | One Year | Power(W): | 24kw |

| Blow Moulding Type: | Stretch Blow Moulding | ||

| Highlight: | Bottle Injection Machine,Bottle Making Machine |

||

Product Description

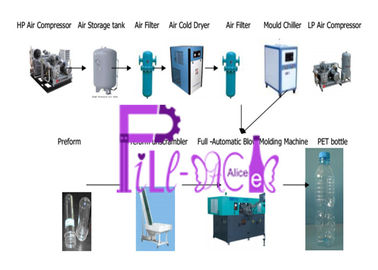

2L 2000BPH Carbonated Bottle Blow Molding Machine Double Cavity Automatic

Product Description

1, Machine specification :

FP-2000 type Automatic blow molding machine is suitable for blowing PET bottles of various shapes,

volume from 100 ml to 2000 ml, wide application for blowing mineral water bottles, soda bottles,

cola bottles..etc

1 .Adopts advanced microcomputer control system, stable performance, the conveyor automatically

send embryo;

2, Use infrared heating lamps, penetrating power strong, embryo heated while rotation, orbital

revolution, heating uniformity, rapid and reliable;

3, Light tube in heating area, reflector width and height can be adjusted to suit the different

structure preform heating, and automatic exhaust temperature device in order to ensure constant

temperature of the drying tunnel;

4, Each machine has a safety self-locking device, when a processes have problem, the program will

automatically switch to a safe state;

5, All the action drive by the cylinder, do not use pumps, with no pollution, low noise;

6, Gas way design divide action and air blowing into three parts, action to meet the needs of the

different pressure of the blowing, action;

7, Cooling system to achieve the desired cooling effect; H- the bottle scrap rate less than 0.2%.

8, Pneumatic mould clamping made more stable operation; Blowing from bottom to top give higher

correctness;

Main parameter of the bottle blowing machine:

| Main parameter | ||

| Model | FP-2000 | |

| Container | Product material | PET,PP,PE |

| Volume | 0.1l-2l | |

| Applicable bottle height | 50-350mm | |

| Applicable bottle body diameter | 20-92mm | |

| Theoretical output | 2000-2400pcs/h(0.5l) | |

| Moulding | Max. mould plate Dimenstion(L*W) | 450*490mm |

| Max.mould thickness | 180mm | |

| Machine size and weight | Main machine (L*W*H) | 2500*1650*1850MM |

| Main machine weight | 3200Kg | |

| Preform unscrambler(L*W*H) | 2000*950*2480mm | |

| Heater weight | 250Kg | |

| Install Power-Using power | 18kw | |

Features:

1) The theoretical output of the automatic carbonated bottle blowing maching is 2000 to 2400 pcc/h(0.5L)

2) The production bottle from 0.1L to 0.2L

3)This product has a stable production performance and advanced PLC system, through man-machine interface to complete the machine control, making the operation easier to adjust.

4). Operated only by one person without special training.

5)Heating temperature and blowing time can be adjusted according to different bottles.

6)With automatic preform unscrambler, the human cost is reduced, and the production efficiency is improved.

7)The maintenance is simple and the whole process is fully automatic.

Detailed Images

Packing & Delivery![]()

![]()

![]()

![]()

Delivery time:

The machines will be made within 30-35 working days after the bottle design are confirmed;

Payment:

30% T/T deposit within five days after the contract is signed against invoice of the seller. The

balance of 70% T/T before shipment OR 100% irrevocable transferable L/C.

FAQ

1.Why do you choose our factory?

There are many foreign guests cooperate with our company.We have enough experience and fund to provide you the high-quality products with the best price.

2.How long can you delivery?

About 30 days after we received the deposit(30%T/T in advance,70%T/T before shipment.)

3.How about your after-sale service?

One year repair for free Seller responsible for arrange engineer for installation and guide the workers of buyer how to operate and necessary repair,and give buyer a turnkey project.

4.How long can you finished the installation?

About 10-15 days.If the water and electricity is ready.If you have any questions,please do not hasitate to contact me.

![]()

please kindly click the play button to watch the video