10pcs/Min Shrink Bottle Seal Packing Machine For Beverage Bottle

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE. ISO9001 |

| Model Number: | WD-150A |

| Operation mode: | Automatic / manual |

|---|---|

| Automation: | PLC control |

| Application: | Shrink wrapping for containers |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set/pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Sea worthy package |

| Delivery Time: | 35-40 days after deposit receipt |

| Payment Terms: | TT / LC / |

| Supply Ability: | 1 set / month |

|

Detail Information |

|||

| Highlight: | 10pcs/min bottle seal packing machine,PLC bottle seal packing machine,PLC automatic bottle packing machine |

||

|---|---|---|---|

Product Description

0-10 pcs/min production speed automatic Shrink packing machine for beverage bottle

Product description

● Frequency converter speed adjust,two segment convey device.

● Bottle pushing, thermo sealing and cutting whole movement adopt to pneumatic fracture.

● Proximity switch control film length.

● Touch screen, PLC system greatly increase facility movement reliability.

● Double-wind recycle fan machine, ensure shrinkage tunnel inside even temperature.

● Super big wind-volume cooling system, ensure quickly get into shape .

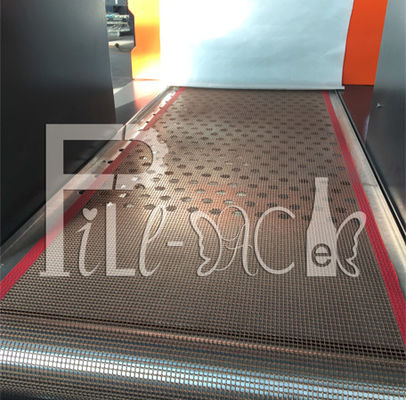

● Anti-high temperature teflon convey belt, convey steadily, high-strength anti-abrasion.

● Frequency limitless speed adjust convey belt frame.

● Convey belt height can make according client requirement, adjust range:±50mm

● Bottle convey machine can meet with client bottle forward direction requirement, can lengthen or shorten.

● Wing stainless steel heating system, endurance.

● Meet with product instant stop requirement product-bearing rack device ensure production line consistency.

Function

1. Auto convey fracture; joint filling machine convey belt, divide two passage or one passage, control via frequency converter, speed adjust freely, can auto divide and sort bottles .

2. Automatic film wrappage fracture, cam complete wrappage auto film covering and sealing, cutting function.

3. Auto thermo shrinkage cooling fracture, can auto contraction and cooling function after film covering.

Production procedure for bottle shrink wrapper

Wrappage from single-line 90°change to multi-line again divide 1,2,3,4 line via bottle division board, via the front 1,2,3,4 bottle separately reach photoelectric inspection, convey belt stop, place-limit gas-cylinder work, wrappage was conveyed to cutting and sealing machine to seal and cut, wrappage was conveyed to contraction machine to contract via convey device, again convey to stock rack via cooling convey belt, when the first bag convey to contraction machine, the second bag auto arrange, then conveyed to sealing and cutting machine via pushing cylinder, again repeat the first bag recycle procedure.

Technical condition and requirement

1. Package type

(1)350/500/550/600ML big bag:4×6,4×5 ;small bag,3×4,3×5 four type of package.

(2)1L/1.5L/2L/2.5L big bag:3×3,3×4;small bag,2×2,2×3 four type of package

2. Regarding can, we suggest adopt to package with tray, pack steadily.

3. Meet with pre-treatment filling speed of filling machine.

(1) 350/500/550/600ML big bag:4×6,4×5,(12000-15000b/hr),small bag:3×5,3×4,(8000-10000b/hr).

(2)1L/1.5L/2L big bag:3×4,3×3(5000-6000b/h), small bag:2×3,2×2(3000-4000b/hr).

Solution for bottle shrink wrapper

1. According production line, auto arrange, and combine our company MB-150A automatic sealing and cutting mature structure, as the machine fracture.

2. The production line can match with any company filling device. For it stability, the production line main component all adopt to import, joint venture famous brand.

3. If pre-treatment filling machine output is comparatively high, can divide two-way, auto seal and cut at the same time, to meet with output requirement, among WD-150A fracture has original creation, it is the highest-efficiency, highest economical collocate at the same time.

4. PE film adopt to flake, upper and down roll, auto seal and cut to roll type and up to shrinkage efficiency.

| no | Name | spec | number | brand | |

| 1 | board production component | ||||

| 2 | Plant metal component | ||||

| 3 | pneumatic component | 1 | Taiwan Airtec | ||

| 4 | Electric controlling component and accessory | ||||

| Photoelectric switch | 4 | South Korea Autonics | |||

| Proximity switch | 2 | South Korea Autonics | |||

| PLC | 1 | Thinget | |||

| Touch screen | 1 | Thinget | |||

| Frequency converter | 3 | Taiwan Telta | |||

| AC contactor | 3 | France Schneider | |||

| Mid-relay | 8 | France Schneider | |||

Competitive Advantage:

1. One year warranty for the whole system

2. Free equipment installation and debugging

3. After one year, we can help you to maintain the machine and the accessories are provided only one the cost price

4. Every 3 years, we can help to overhaul the machine free (Labor)

5. We can provide internship service and help you train the operator and mechanic

6. Free production technology and process configuration

7. We can help you to design the production line, workshop and provide turn-key project

please kindly click the play button to watch the video