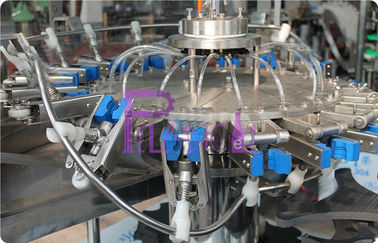

Stainless Steel Carbonated Drink Filling Machine , CSD Bottle Automatic Capping Machine

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE & ISO & TUV & SGS |

| Model Number: | DG -12 |

| Color: | Silver Gray |

|---|---|

| Control: | PLC Control With Touch Screen |

| Processing: | Japan & Germany |

| Suitable Bottle Size: | 0.3-2L PET Bottle |

| Cap Style: | Plastic Screw Cap |

| Capacity: | 2000-3000BPH |

| Electrical Brand: | Mitsubishi, OMRON, SIEMENS |

| Warranty: | 1 Year for Spare Parts |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Case Package |

| Delivery Time: | 30 Working Days After Receiving Your Deposit Payment |

| Payment Terms: | TT & L/C |

| Supply Ability: | 20 sets/month |

|

Detail Information |

|||

| Highlight: | soft drink bottling equipment,coke filling machine |

||

|---|---|---|---|

Product Description

Stainless Steel Carbonated Drink Filling Machine , CSD Bottle Automatic Capping Machine

Quick Detail:

Name: Stainless Steel Linear Filling Machine CSD Bottle Automatic Capping Machine

Material: Food stage stainless steel

Control: PLC & touch screen control

Capacity: 3000-4000bph

Suitable Bottle: PET bottle

Bottle Volume: 0.3-2L

Dimension: By order

Function: Washing filling capping 3 functions

Technology: Germany & Japan

After-sales service provided: Engineers available to service machinery overseas .

Description:

This stainless steel linear filling machine CSD bottle automatic capping machine is suitable for packing beverage containing gas. Its performance is as below: all parts, for instance, filling valve, which directly contact medium are made of stainless steel or harmless material. So it conforms to the requirements of food sanitation. Sealing parts are made of heat-proofing rubber, in order to meet the technique requirements of users to sterilization at high temperature. Using programmable controller to realize fully automatic control from bottles entering to packing finished.

Using transducer as speed regulator, so the user can regulate the machine easily to suit different power requirements. Adopting equal pressure filling principle and current spring valves in order to assure the beverage quality. Using advanced magnetic coupler to regulate cap-screwing torque, in order to assure capping quality.

Characteristics:

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopts advanced PLC automatic control technology, the key electrical component from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Specifications:

| Model : | DG -8 | DG -12 | DG-18 | DG -24 |

| Production Capacity: | 1000-2000b/h | 1000-3000b/h | 2500-4600b/h | 2500-6000b/h |

| Bottle standard: | Glass bottle, PVC bottle, Pop-top can | |||

| Filling Pressure: | 0.2-0.3Mpa | |||

| Filling Temperature: | 2-6° | |||

| Power: | 0.75kw | 1.1kw | 1.5kw | 1.5kw |

| Overall Dimensions: | 1000×900×1800 mm | 1100×1050×1800 mm | 1400×1300×1800 mm | 1600×1540×1800 mm |

| Weight : | 1000kg | 1600kg | 2100kg | 2700kg |

Competitive Advantage:

1. One year warranty for the whole system

2. Free equipment installation and debugging

3. After one year, we can help you to maintain the machine and the accessories are provided only one the cost price

4. Every 3 years, we can help to overhaul the machine free (Labor)

5. We can provide internship service and help you train the operator and mechanic

6. Free production technology and process configuration

7. We can help you to design the production line, workshop and provide turn-key project

please kindly click the play button to watch the video