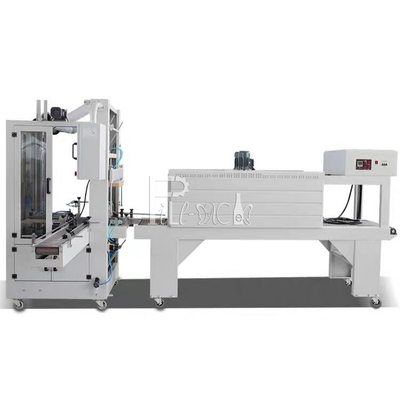

PE Film Shrink Wrapping Packaging Machine L Type PET Mineral Water Beer Beverage Can

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | FP-150B |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | 7000USD |

| Packaging Details: | Wooden case |

| Delivery Time: | 15-20 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Max Output Per Minute: | 8 Bags/min | Suitable Type: | Glass Bottle,pop Can,PET Bottle |

|---|---|---|---|

| Shrink Film: | PE,PVC,POF | Maximum Film Width: | 58cm |

| Shrinkage Thermos Thickness: | 0.03-0.15mm | Function: | Shrink Wrapping Machine |

| Fan Machine: | 2set | Working Pressure: | 5-7kgf/㎡ |

| Dimension(L*W*H): | 3600*2000*1900MM | Weight: | 450KG |

| Highlight: | 8bags/min PE Film Shrink Wrapping Machine,PE Film Shrink Wrapping Packaging Machine,0.15mm PE Film Shrink Wrapping Machine |

||

Product Description

Full Automatic L Type PET Mineral Water beer beverage Bottle Can PE Film Shrink Wrapping Packaging Machine Equipment

Product description:

●The sealing and cutting knife row is equipped with a safety sensor. When the package is overturned or the operator reaches in, the protection system will automatically start the cutting knife to stop cutting, and automatically bounce back to reset, which plays a role in safety protection.

●The machine has an emergency stop function, press the emergency stop button, the machine will stop all work.

●The sealing and cutting knife adopts American DuPont Teflon coated alloy knife with anti-sticking and high temperature resistance. The sealing line is strong and will not crack, coking and smoke.

●The single-shot detection photo electricity can accurately detect the position of the packaged items. Using the original "OMRON" digital temperature controller, built-in PID function, the temperature of the sealing knife is sensitive and accurate, and can be set at will. Don't worry about inaccurate temperature hurting the product.

●Double-wind recycle fan machine, ensure shrinkage tunnel inside even temperature.

●Can pack larger and more items, especially suitable for packaging beverages, beer, mineral water, oil class etc. Improve efficiency and good packaging effect.

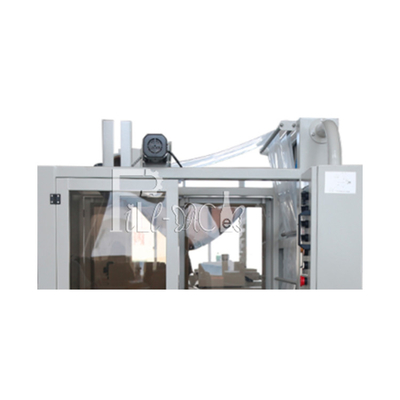

●Automatic feeding, cutting, heat sealing and shrinking are automatically completed in one line, and it can also be connected with feeding production line and packaging production line to realize assembly line operation, improve work efficiency and save labor costs.

●The electronic speed regulator is used for speed regulation, which can adjust the speed steplessly to ensure the smoothness of the conveying and good shrinkage effect; the copper wire motor is used for low noise and long service life; The stainless steel wing-type heating tube is used, the heat is uniform, and the thick asbestos layer is used to save electricity and keep warm (more than 15% electricity).

Solution:

1,according production line, auto arrange, and combine our company FP-150B automatic sealing and cutting mature structure.

2,the production line can match with any company filling device. For it stability, the production line main component all adopt to import, joint venture famous brand.

3,if pre set filling machine output is comparatively high, can divide two-way, auto seal and cut at the same time, to meet with output requirement, among FP-150B has original creation, it is the highest-efficiency, highest economical collocate at the same time.

4,PE film adopt to flake, upper and down roll, auto seal and cut to roll type and up to shrinkage efficiency.

Production procedure:

Product entrance one by one and detecting by sensor, sensor to count as preset number to stop and push a line,4 0r 6 lines will be grouped into a pack, wrap page was conveyed to cutting and sealing machine to seal and cut, wrap page was conveyed to contraction machine to contract via convey device, again convey to stock rack via cooling convey belt, when the first bag convey to contraction machine, the second bag auto arrange, then conveyed to sealing and cutting machine via pushing cylinder, again repeat the first bag recycle procedure.

|

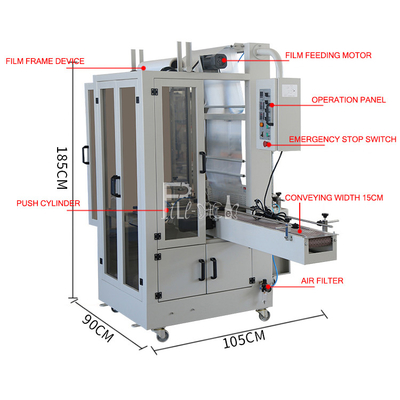

Film wrapping machine head technical parameter

|

|

|

Suitable max weight

|

20KG

|

|

Maximum film width

|

58CM

|

|

shrinkage film type

|

PE,PVC,POF

|

|

shrinkage thermos thickness

|

0.03-0.15mm

|

|

max output per minute

|

8bags/min

|

|

Power

|

1.5KW

|

|

Hot plate Power

|

1.3KW

|

|

Working pressure

|

5-7kgf/㎡

|

|

Conveyor height

|

80+5cm(adjustable)

|

|

facility weight

|

210KG

|

|

Film wrapping machine head size

|

L1050*W900*H1850MM

|

|

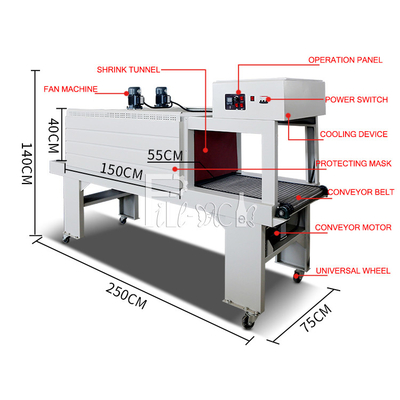

Shrink tunnel technical parameter

|

|

|

Conveyor speed

|

0-10m/min

|

|

Power

|

18KW

|

|

Fan machine

|

2 SETS

|

|

Bearing weight

|

40KG

|

|

Shrink tunnel heating part size

|

1500*550*400mm

|

|

Dimension

|

2500*750*1400mm

|

|

Weight

|

240KG

|

Spare Parts:

![]()

![]()

|

Part

|

Brand

|

|

Cylinder

|

AIRTAC

|

|

Electric relay

|

OMRON

|

|

Photoelectric sensor

|

OMRON

|

|

Motor

|

Trinity

|

|

Cutter

|

Teflon coated alloy steel

|

|

Temperature control meter

|

Domestic

|

|

Timetable

|

Domestic

|

|

Fan machine

|

Domestic

|

Applicaton:

![]()

![]()