Bottled Bottle Packing Machine Movable Juice Pasteurizer Recycling With Spray Nozzles

Product Details:

| Place of Origin: | China,JiangSu,Zhangjiagang |

| Brand Name: | FillPack |

| Certification: | CE. ISO9001 |

| Model Number: | PL |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set/pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Sea worthy package |

| Delivery Time: | 25 days after deposit receipt |

| Payment Terms: | TT / LC / |

| Supply Ability: | 1 set / month |

|

Detail Information |

|||

| Capacity: | 8000-10000BPH / Customize | Process Type: | Bottled Juice Pasteurizer |

|---|---|---|---|

| Voltage: | 380V 3phase 50HZ / Customize | Bottle Type: | Various Bottles |

| Temperature Zone: | 4 Sections / Customize | Power: | 6kw |

| Highlight: | Sterilizer System,Bottle packaging machine |

||

Product Description

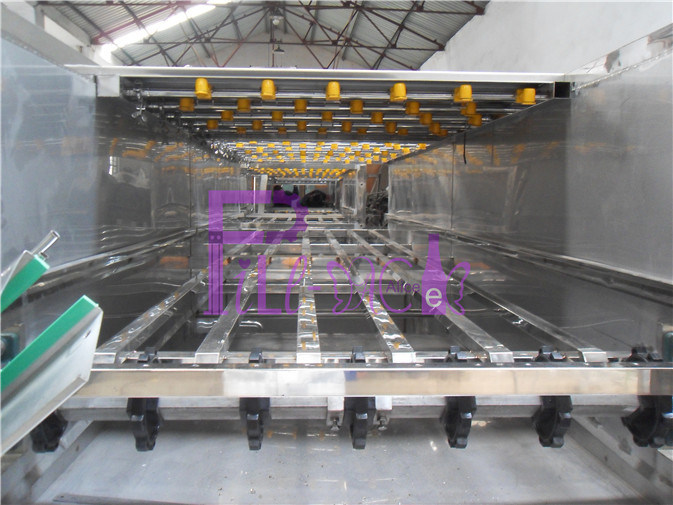

Bottled Movable Juice Pasteurizer Recycling With Spray Nozzles

Quick Detail:

1, Processing type: Bottle cooling and warming machine

2, Bottle type: Various bottes

3, Working temperature: Room temperature

4, Recycling tank for saving energy

5, Heating manner: steam heating and electric heating

6, Temperature zone: 4 sections / customize

Description:

The bottled juice pasteurizer is applied to PET bottle tea or juice hot filling production line and PET bottle carbonated drink filling production line. For hot filling, it can put down the temperature of hot filling drink to 36-40. For low -temperature filling, it can get up the temperature to 36-40 to eliminating the condensed water on the external wall of PET bottes, to keeping bottles dry and clean. So convenient to following-up labeling and packing process.

Features:

1. Several temperature zones will be designed basing on production capacity, processing requirement etc;

2, All the pumps are Nanfang pump;

3, The top plate can be removed for easy maintainence;

4, There is recycling tank in the bottom for saving energy;

5, Two heating manners: steam heating & electric heating;

6, Suitable for juice / tea filling line, hot filling line, beer filling line, soft drink filling line etc;

Specifications:

| Production capacity (BPH) | 3000-5000 | 6000-9000 | 10000-15000 | 24000-36000 |

| Heating temperature (℃) | 37-45 | 37-45 | 37-45 | 37-45 |

| Cooling time (min) | 12-15 | 12-15 | 12-15 | 12-15 |

| Linear conveyoring speed (m/min) | 100-550 | 100-550 | 100-550 | 100-550 |

| Width of mesh conveyor (mm) | 1.22 | 1.22 | 1.22 | 1.22 |

| Vaport pressure (Mpa) | < 0.4 | < 0.4 | < 0.4 | < 0.4 |

| Vapor consumption (kg/h) | 80 | 120 | 240 | 280 |

| Water circulation volum (m3/h) | 6 | 9 | 15 | 28 |

| Installed power (kw) | 6 | 7.55 | 8.6 | 18 |

| Dimension (L*W*H) | 620*1500*1700 | 1580*1500*1700 | 1580*1800*1700 | 22000*800*1700 |

| Weight (KG) | 2500 | 3200 | 4300 | 5600 |

Competitive Advantage:

1. One year warranty for the whole system

2. Free equipment installation and debugging

3. After one year, we can help you to maintain the machine and the accessories are provided only one the cost price

4. Every 3 years, we can help to overhaul the machine free (Labor)

5. We can provide internship service and help you train the operator and mechanic

6. Free production technology and process configuration

7. We can help you to design the production line, workshop and provide turn-key project

please kindly click the play button to watch the video